In the realm of precision engineering, the significance of advanced machining techniques cannot be overstated. Among these, 5 axis machining stands out as a pivotal method that dramatically enhances the accuracy and efficiency of manufacturing processes. As industry expert Dr. Emily Hartman aptly states, "5 axis machining is not merely an option; it is a necessity for achieving the intricate designs demanded by modern engineering." This revolutionary approach allows manufacturers to work on multiple sides of a component in a single setup, thus minimizing error and maximizing productivity.

The ability to manipulate components from various angles is crucial in producing complex geometries and precise tolerances that are increasingly required across industries, from aerospace to medical devices. The integration of 5 axis machining into engineering solutions not only streamlines production but also reduces lead times and material waste, cementing its role as an essential component in the manufacturing landscape. By embracing this technology, engineers can ensure they meet the evolving challenges of precision while maintaining competitive advantages in an ever-demanding market.

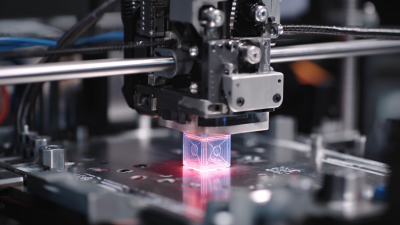

Five-axis machining is becoming increasingly essential in the realm of precision engineering, especially for industries that demand tight tolerances. The ability to manipulate tools along five axes simultaneously allows manufacturers to achieve complex geometries and enhance precision in their products. Recent advancements in CNC machining technology have demonstrated a strong response to the rising demand for precision in sectors like aerospace and drone manufacturing. Companies are now able to deliver components that meet stringent specifications more quickly and efficiently, ultimately improving their competitive edge.

Five-axis machining is becoming increasingly essential in the realm of precision engineering, especially for industries that demand tight tolerances. The ability to manipulate tools along five axes simultaneously allows manufacturers to achieve complex geometries and enhance precision in their products. Recent advancements in CNC machining technology have demonstrated a strong response to the rising demand for precision in sectors like aerospace and drone manufacturing. Companies are now able to deliver components that meet stringent specifications more quickly and efficiently, ultimately improving their competitive edge.

Tips: When considering the implementation of five-axis machining in your operations, evaluate your current machining capabilities and identify areas where complexity and precision can be beneficial. Moreover, staying abreast of market trends and emerging technologies will help you make informed decisions when investing in machinery.

In addition, as the European market anticipates growth in multi-axis machining centers, it's crucial to recognize the adaptability offered by five-axis systems. These advancements help address the evolving needs of precision engineering and promote innovation. By leveraging cutting-edge technology, manufacturers can navigate the challenges of meeting tight tolerances while also fostering a culture of continuous improvement within their operations.

The advancements in 5-axis machining technology are shaping the landscape of precision engineering, particularly as we approach 2025. According to recent market research, the global precision tool market is projected to expand significantly, growing from USD 231.78 billion in 2025 to USD 346.38 billion by 2033. This surge illustrates the increasing demand for sophisticated machining solutions that can deliver unparalleled precision and efficiency in manufacturing processes.

Emerging trends in 5-axis CNC machining reveal that industries are embracing these advanced technologies to enhance productivity and accuracy. The CNC machine market alone is expected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, further underscoring the pivotal role that innovative machining solutions will play in various sectors. As companies aim for competitive advantages, the integration of 5-axis technology will be vital in meeting market demands while also pushing the boundaries of what is possible in precision engineering.

| Dimension | 2023 Data | 2024 Projections | 2025 Projections |

|---|---|---|---|

| Market Size (USD Billion) | 3.8 | 4.2 | 4.8 |

| Annual Growth Rate (%) | 7.2 | 8.0 | 8.5 |

| Number of 5 Axis Machines Installed | 12,000 | 13,500 | 15,000 |

| Percentage of Precision Engineering Firms Using 5 Axis Machining (%) | 35 | 42 | 50 |

| Average Tool Change Time (Minutes) | 2.5 | 2.0 | 1.5 |

5-axis machining has become a crucial component in the realm of precision engineering, particularly when it comes to cost management. Traditional machining methods often require multiple setups and extensive manual labor to achieve complex geometries. In contrast, 5-axis machining enables manufacturers to produce intricate parts in a single setup, significantly reducing the time and labor costs associated with production. By minimizing the need for tool changes and multiple equipment setups, businesses can streamline their manufacturing processes, leading to a marked reduction in overall production expenses.

Moreover, the ability to create highly complex shapes with unparalleled precision means that parts can be manufactured to tighter tolerances. This reduces the likelihood of rejects and the costs associated with rework. Over time, the initial investment in 5-axis machining technology is offset by these savings, as manufacturers enjoy improved efficiency and lower waste levels. As a result, companies can not only enhance their product quality but also achieve a substantial competitive advantage in an increasingly demanding market.

5-axis machining has emerged as a pivotal technology in the aerospace and automotive sectors, offering significant advantages in precision engineering. This machining method allows for the manipulation of the workpiece from multiple angles, enabling the fabrication of complex geometries that are increasingly prevalent in advanced engineering applications. For instance, in aerospace, where components often include intricate designs with tight tolerances, 5-axis machining provides the capability to achieve better accuracy and surface finish, thereby enhancing overall product performance and safety.

Case studies highlight the successful integration of 5-axis machining in automotive engineering, where manufacturers have reported reductions in both production time and costs. The ability to complete multiple machining operations in a single setup minimizes material waste and significantly streamlines the manufacturing process. As the global CNC machine market is projected to grow significantly—rising from $101.22 billion in 2025 to $195.59 billion by 2032 at a CAGR of 9.9%—the demand for sophisticated machining techniques, including 5-axis capabilities, will continue to rise, driven by the need for higher precision and efficiency in various engineering applications.

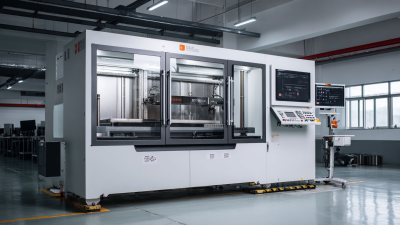

The integration of artificial intelligence (AI) and automation is poised to significantly enhance the efficiency of 5-axis machining by 2025. As the global CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, the upward trend indicates a strong demand for precision engineering solutions that leverage advanced technologies. AI's ability to optimize machining processes and reduce operational downtimes will contribute to this growth, with studies estimating that AI could increase productivity by 1.5% by 2035 and further accelerate GDP growth.

At the forefront of this evolution, innovations in automated machines and collaborative robotics are transforming the landscape of precision engineering. For instance, events like EMO Hannover 2025 showcase cutting-edge technologies, including AI-driven 5-axis machining centers connected to robotic systems, designed to raise productivity levels. Additionally, the end milling machine market is expected to expand, segmented by factors such as automation grade and application, reflecting the industry's shift towards smarter, more efficient manufacturing practices. As these advancements unfold, the role of AI and automation in precision engineering will be crucial for maintaining competitiveness and achieving higher operational efficiency.

© Copyrights Levil Technology Corp 2022