In the rapidly evolving landscape of manufacturing, the choice of machining equipment plays a pivotal role in determining productivity and precision. Among the myriad options available, the 5 axis mill stands out as a game-changer, offering unmatched versatility and efficiency. As industry expert Dr. John Adams, a leading figure in CNC technology, aptly puts it, "The 5 axis mill not only enhances machining capabilities but also opens doors to complex geometries that traditional mills simply cannot achieve."

By allowing simultaneous movement along multiple axes, the 5 axis mill eliminates the need for multiple setups, significantly reducing production time and improving accuracy. This advanced machining technique is particularly beneficial for industries that demand high precision, such as aerospace, automotive, and medical device manufacturing.

In this article, we will delve into the key benefits and considerations of adopting a 5 axis mill, exploring how this technology can transform manufacturing processes and drive innovation. Whether you're a seasoned professional or new to the field, understanding the advantages and potential of a 5 axis mill can be instrumental in making informed decisions for your machining needs.

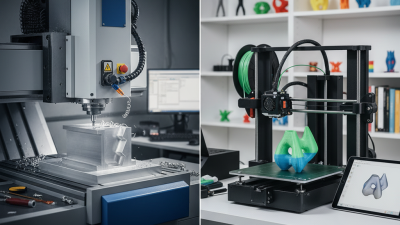

5-axis milling machines represent a significant advancement in machining technology, allowing for greater precision and versatility in manufacturing processes. Unlike traditional 3-axis mills that restrict cutting operations to three linear movements, 5-axis machines incorporate two additional rotational axes. This enhanced capability allows for complex geometries and intricate designs to be machined in a single setup, minimizing the need for time-consuming repositioning and improving overall efficiency.

Understanding the basics of 5-axis milling involves recognizing its unique configurations. The axes typically involve two rotational movements around the X and Y axes, and three linear movements along the X, Y, and Z axes. This arrangement enables the cutting tool to approach the workpiece from virtually any angle, which is particularly advantageous for creating components with complex contours, such as aerospace parts, medical devices, and intricate molds. Moreover, the ability to maintain more precise tool paths significantly lowers the risk of errors, facilitating higher quality outcomes and reducing material waste during production.

| Dimension | Description | Benefits | Considerations |

|---|---|---|---|

| Versatility | Ability to machine complex parts from multiple angles. | Increases efficiency by reducing setup time. | Requires skilled operators for effective use. |

| Precision | High accuracy in machining due to reduced uncertainty in tool path. | Improved surface finish and tighter tolerances. | Higher initial investment and maintenance costs. |

| Complex Geometries | Ability to produce intricate designs that would be difficult on 3-axis machines. | Enhances product design possibilities. | Programming complexity can increase with sophisticated designs. |

| Time Efficiency | Capable of completing machined parts in fewer setups. | Reduces lead times for production. | Requires advanced CNC programming knowledge. |

When it comes to modern machining, the advantages of 5-axis milling over traditional methods are substantial. One of the key benefits is the ability to achieve complex geometries in a single setup, significantly reducing production time and minimizing the need for additional fixturing. According to a report by the Association for Manufacturing Technology, 5-axis machines can enhance productivity by up to 30%, as they allow for continuous cutting without the need to reposition the workpiece. This leads to improved accuracy and a reduction in the risk of errors that can occur during multiple setups.

Another major advantage lies in the improved surface finish and precision that 5-axis milling offers. Traditional 3-axis mills often require additional passes to achieve desired angles and contours, which can compromise dimensional accuracy. In contrast, 5-axis machines can handle intricate designs with ease, enabling manufacturers to meet stringent tolerances. Industry studies suggest that utilizing 5-axis milling can lead to a 40% reduction in finishing time, making it a worthwhile investment for businesses aiming to stay competitive in a fast-evolving market.

Tips: When considering a transition to 5-axis milling, it’s essential to evaluate the complexity of the parts you intend to manufacture. Investing in proper training for your operators can also maximize the benefits of this advanced technology. Regular maintenance of your milling machines ensures optimal performance and longevity, helping to safeguard your investment over time.

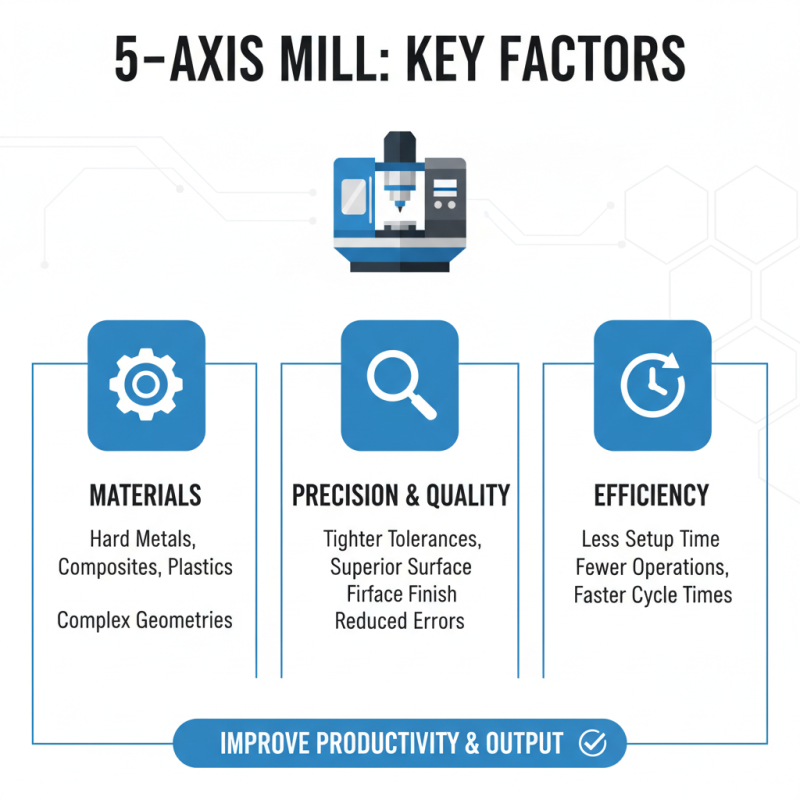

When considering a 5 axis mill for your projects, it's essential to evaluate several key factors that can significantly impact your machining efficiency and output quality. First and foremost, you should assess the types of materials you’ll be working with. If your projects involve complex geometries or hard materials, a 5 axis mill’s ability to position the workpiece in multiple orientations can lead to improved precision and reduced setup time.

Another important consideration is the complexity of your designs. If you regularly work with intricate shapes or detailed surfaces, a 5 axis mill can enhance your capability to create highly detailed parts with fewer machining steps. This not only streamlines the production process but also minimizes the chances of human error during setups.

**Tips:** Always examine the machine’s capabilities in relation to your specific needs. Look for features like control software, rigid construction, and tool accessibility. Additionally, consider future project demands; investing in a 5 axis mill that can adapt to evolving project requirements will pay off in the long run, ensuring that your workflow remains efficient and competitive.

5 axis milling has become a transformative technology across various applications and industries, providing significant advantages in precision and efficiency. In the aerospace sector, for instance, components such as turbine blades and intricate engine parts can be machined with unmatched accuracy. The ability to manipulate the workpiece in multiple orientations allows for complex geometries to be produced in a single set-up, reducing the need for multiple fixtures and setups that can introduce errors and increase production time.

In the medical field, 5 axis milling is instrumental in creating highly customized implants and surgical instruments. The technology enables the production of intricate designs tailored to individual patient anatomy, enhancing the effectiveness of medical devices. Moreover, the automotive industry benefits immensely from 5 axis milling, allowing for the creation of lightweight yet robust components, which are essential for improving fuel efficiency and overall vehicle performance. As industries continue to seek innovative solutions to meet rising demands, the versatility of 5 axis milling will undoubtedly play a crucial role in shaping the future of manufacturing.

This chart illustrates the scoring of how various industries benefit from 5-axis milling technology. A scale from 1 to 10 indicates the perception of benefits across sectors such as Aerospace, Automotive, Medical, Mold Making, and Energy. The results highlight the advantage of precision and efficiency that 5-axis milling offers, particularly in the aerospace and automotive sectors.

Investing in 5-axis milling technology presents a significant opportunity for manufacturers aiming to enhance their machining capabilities and efficiency. According to a report by the Freedonia Group, the global demand for machine tools, including advanced milling systems, is expected to reach $140 billion by 2025, driven by the need for precision and efficiency in production processes. With 5-axis mills, companies can increase their production speed and precision by reducing the need for multiple setups, which can save time and labor costs. Additionally, a study from Market Research Future indicates that the 5-axis machining market will grow at a CAGR of 6.5% from 2021 to 2027, underscoring the technology's rising importance in the industry.

Despite the higher initial cost associated with 5-axis milling machines, the long-term return on investment (ROI) can be substantial. A report from QY Research highlights that companies employing 5-axis machining can reduce cycle times by up to 50% and minimize material waste, leading to increased profitability. Furthermore, the ability to produce complex geometries in a single setup enhances the versatility of manufacturing operations, allowing firms to cater to diverse client needs more effectively. By evaluating the cost implications and prospective ROI, organizations can make informed decisions about integrating 5-axis milling technology into their processes, paving the way for improved operational efficiency and market competitiveness.

© Copyrights Levil Technology Corp 2022