In the world of precision engineering, 3D CNC machines play a pivotal role. With advancements happening rapidly, industry experts are closely watching trends. Dr. Emily Jensen, a leading figure in the 3D CNC field, recently stated, “The future of machining lies in automation and precision.” This insight highlights the growing significance of 3D CNC technology.

As we approach 2026, engineers and manufacturers face new challenges. The demand for high precision and efficiency in production is unrelenting. 3D CNC machines are becoming essential tools in achieving these goals. Many companies are investing heavily in upgrading their technologies. However, not all machines meet the required standards of reliability and performance. Choices must be made carefully.

The landscape is competitive and constantly evolving. Companies must reflect on their needs and capabilities. Are they ready to integrate cutting-edge 3D CNC solutions? The answer could define their future. It's crucial to balance innovation with practical requirements. In the end, the right machine could elevate an entire production line.

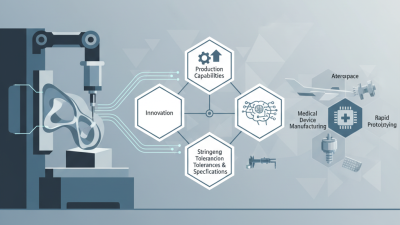

3D CNC machines have transformed precision engineering significantly. They allow for intricate designs and complex geometries. With their high precision, these machines can create parts with tight tolerances. This is crucial in fields like aerospace and medical device manufacturing. The automated nature of CNC machines reduces human error, which is a common issue in manual machining. However, they come with a steep learning curve.

Operators need extensive training to fully utilize these machines. Understanding software and toolpaths is essential for optimal performance. While 3D CNC technology has advanced, challenges remain. Material limitations persist, which can impact design flexibility. Companies often face issues with maintenance and calibration as well. Despite these hurdles, the investment in 3D CNC machines can yield significant productivity gains.

In recent years, the speed of production has also increased. However, faster does not always mean better quality. Some might sacrifice precision for speed. It's critical to find a balance. The ongoing development in this field suggests that future machines will become even more efficient. There is always a need to evaluate the trade-offs in speed versus quality.

This chart illustrates the performance metrics of various 3D CNC machines that are important for precision engineering. The values represent the effectiveness of each metric on a scale from 0 to 100, providing a clear comparison between accuracy, speed, material flexibility, ease of use, and cost efficiency.

When considering 3D CNC machines for precision engineering in 2026, several key features stand out. High accuracy is paramount. Machines should achieve tolerances of less than 0.1mm. Such precision ensures components fit perfectly. The resolution of the machine plays a critical role in this aspect. A higher resolution allows for intricate designs and smoother finishes.

Speed is another essential factor to think about. Machines with faster feed rates lead to improved productivity. However, speed shouldn't compromise quality. Durability also matters. Look for robust construction materials that can withstand demanding tasks. A machine's ability to handle various materials is crucial, too. Versatility can make a significant difference in project capabilities.

Moreover, user-friendly interfaces are increasingly important. Intuitive software can reduce the learning curve. Users often overlook this aspect. An overly complicated system can hinder workflow. Regular updates and customer support are beneficial. They ensure that users can adapt to new technologies. As machines advance, staying current is vital for maintaining an edge in precision engineering.

In 2026, the landscape of 3D CNC technology is evolving rapidly. As precision engineering becomes more critical, various brands are introducing machines that promise higher accuracy and better reliability. These machines use advanced software for intricate designs. The precision in components is crucial for automotive and aerospace applications. Yet, achieving consistency in 3D printing remains a challenge. Users often face calibration issues that can affect the final product.

Some top models feature multi-axis capabilities. This allows for more complex shapes and structures. There is a noticeable difference in the finish quality of machined parts. However, not all machines deliver this precision equally. Some models struggle with fine details, leading to user frustration. The need for regular maintenance is also a concern. Keeping machines in optimal condition is essential to avoid production delays.

Another area for reflection is the cost of these machines. While some offer incredible functionality, the price can deter many small businesses. Balancing the budget with quality is crucial. Users must evaluate their requirements carefully. Sometimes, the most advanced models are not necessary for every project. It's about finding the right fit for specific needs and capabilities.

3D CNC machines have transformed various industries by enabling high precision in manufacturing. These machines find extensive applications in sectors like aerospace, automotive, and medical device production. For instance, they create intricate components that meet stringent quality standards. In the aerospace industry, precision parts must withstand extreme conditions. A small error can lead to significant safety risks.

In the medical field, 3D CNC machines produce custom implants and prosthetics. Personalized solutions enhance patient outcomes. However, the challenge lies in ensuring every piece is perfect. Even minor flaws can lead to complications in surgery. Additionally, the automotive sector uses these machines for prototyping. Rapid iterations can streamline design processes but also introduce potential for mistakes during scaling.

Beyond perfect engineering, these machines require skilled operators. Training is essential to maximizing their capabilities. Operators must interpret complex designs and understand materials. Despite advancements, not every project will achieve flawless results. This reality poses ongoing challenges in precision engineering, requiring continuous improvement.

| Machine Model | Max Cutting Volume (mm³) | Precision (µm) | Speed (mm/min) | Weight (kg) | Industry Applications |

|---|---|---|---|---|---|

| Model A | 5000 | 5 | 1200 | 150 | Aerospace, Automotive |

| Model B | 3000 | 3 | 1000 | 120 | Consumer Electronics, Medical Devices |

| Model C | 7000 | 2 | 2000 | 200 | Industrial Machinery, Defense |

As we look to the future of 3D CNC machinery in 2026, precision engineering continues to evolve. New materials and advanced software are reshaping how we approach design. Increased automation is a great trend. Machines will soon handle complex tasks with minimal human intervention. This shift may raise questions about job security in the industry.

Moreover, innovations such as enhanced sensor technology are coming into play. These sensors provide real-time feedback, ensuring accuracy and reducing waste. Imagine a machine that can correct itself mid-process, responding dynamically to environmental changes. This could revolutionize manufacturing efficiency. However, the dependence on such technology might also lead to oversights. Relying too heavily on automation may suppress fundamental skills.

Tips: When selecting a 3D CNC machine, consider ease of use. Features should be intuitive. Also, pay attention to the machine's adaptability to new materials. You want a machine that grows with your needs. Evaluate sustainability too. Eco-friendly options are emerging, but they often require more investment. Strive to balance cost with long-term benefits.

© Copyrights Levil Technology Corp 2022