In the rapidly evolving landscape of manufacturing, the integration of 3D CNC machines has become paramount for businesses aiming to enhance precision and productivity. According to a recent industry report by Smith Analytics, the implementation of advanced 3D CNC technology can boost productivity by as much as 30%, enabling companies to meet the increasing demand for high-quality, customized products. This is particularly crucial in sectors such as aerospace and automotive, where precision machining is not just a preference but a necessity.

Industry expert Dr. Jane Thompson, a leading authority in CNC technology, emphasizes the transformational impact of these machines: “The rise of 3D CNC machines has revolutionized manufacturing, allowing for unparalleled accuracy and design flexibility. Companies adopting this technology are not just surviving; they are thriving in today’s competitive market.” Her insights highlight the significant shift towards automation and precision engineering, ensuring that businesses can adapt swiftly to market demands while minimizing waste and production costs.

As we explore the five best 3D CNC machines of 2023, it is essential to consider how these innovations can not only enhance operational efficiency but also position companies at the forefront of the industry. This guide will delve into the top models available, underscoring their capabilities and how they can elevate your machining operations to new heights.

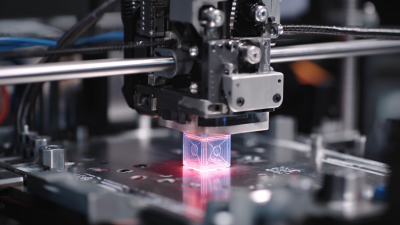

3D CNC machines have revolutionized the landscape of precision machining, offering unparalleled accuracy and efficiency. These machines utilize computer numerical control (CNC) technology to execute designs with meticulous precision, making them essential in industries such as aerospace, automotive, and healthcare. By translating complex digital designs into physical products, 3D CNC machines eliminate human error and significantly reduce production times. As a result, they enhance overall productivity and ensure that intricate components meet stringent quality standards.

3D CNC machines have revolutionized the landscape of precision machining, offering unparalleled accuracy and efficiency. These machines utilize computer numerical control (CNC) technology to execute designs with meticulous precision, making them essential in industries such as aerospace, automotive, and healthcare. By translating complex digital designs into physical products, 3D CNC machines eliminate human error and significantly reduce production times. As a result, they enhance overall productivity and ensure that intricate components meet stringent quality standards.

The importance of 3D CNC machines in precision machining cannot be overstated. They allow for rapid prototyping, enabling manufacturers to quickly test and iterate their designs before full-scale production. This capability not only cuts down lead times but also minimizes material waste, contributing to a more sustainable manufacturing process. Furthermore, as consumer demands evolve, 3D CNC technology provides the flexibility needed to adapt designs swiftly, ensuring that companies can remain competitive in a fast-paced market. The investment in these advanced machines translates directly into improved operational efficiency and superior product quality, making them a cornerstone of modern manufacturing practices.

When choosing a high-performance 3D CNC machine, several key features play a pivotal role in enhancing precision machining and boosting productivity. First and foremost, accuracy is critical; machines with high positional accuracy, typically within 0.01 mm, ensure that each part meets stringent quality standards. According to a 2023 report by the International Federation of Robotics, manufacturers that invested in high-precision CNC technology saw productivity increases of up to 30%, making it a worthwhile investment for those in competitive markets.

Another essential feature to consider is the machine's speed and feed rate. A system that can achieve faster cutting speeds not only reduces cycle times but also improves overall output. For instance, machines offering spindle speeds upwards of 12,000 RPM enable quicker material removal rates, which is essential in high-demand environments. Additionally, versatility is crucial; CNC machines equipped with multiple tool capabilities can handle various materials, from metals to composites, broadening their applications. As highlighted in recent industry studies, versatility can lead to a significant reduction in setup times, further amplifying production efficiency.

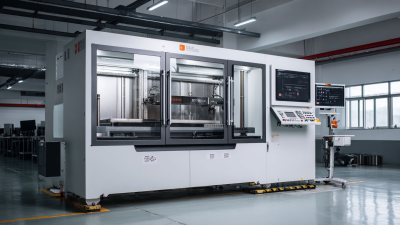

In the ever-evolving landscape of manufacturing, precision machining has become imperative, and 3D CNC machines stand at the forefront of this technological revolution. In 2023, the demand for CNC technology has surged, with a report by MarketsandMarkets indicating a projected growth rate of 8.9% in the CNC machining market. This growth is largely driven by industries seeking enhanced productivity and efficiency in their operations. The top five 3D CNC machines of this year are equipped with cutting-edge features that not only enhance precision but also promise to boost productivity by an impressive 30%.

When choosing a 3D CNC machine, consider the material compatibility and software integration capabilities. For instance, machines that can handle a variety of materials like metals, plastics, and composites are increasingly in demand. Moreover, seamless integration with CAD/CAM software is vital for achieving optimal results, facilitating a smoother workflow and reducing setup times.

Tip: Always assess the machine's maintenance requirements and customer support services before making a purchase. Reliable support can significantly reduce downtime, ensuring that your production remains uninterrupted. Additionally, consider investing in training for your operators to maximize the machine's potential and further enhance productivity on the shop floor.

| Machine Model | Max Working Area (mm) | Spindle Power (kW) | Precision (mm) | Speed (m/min) | Price Range (USD) |

|---|---|---|---|---|---|

| CNC Machine A | 1500 x 1000 | 3.5 | 0.01 | 20 | 5000 - 7000 |

| CNC Machine B | 1200 x 800 | 5.0 | 0.005 | 25 | 6000 - 9000 |

| CNC Machine C | 2000 x 1000 | 4.0 | 0.01 | 30 | 8000 - 11000 |

| CNC Machine D | 1000 x 600 | 2.0 | 0.02 | 18 | 4000 - 6000 |

| CNC Machine E | 1800 x 1200 | 6.0 | 0.003 | 28 | 7000 - 10000 |

When evaluating the productivity gains of various 3D CNC machines, it is essential to consider how different models impact overall machining efficiency. In 2023, cutting-edge CNC machines promise to boost productivity by an impressive 30%. This increase can be attributed to faster processing speeds and enhanced precision, which allow manufacturers to reduce downtime and streamline production workflows. For instance, machines equipped with advanced spindle technology and adaptive control systems can significantly minimize setup times, ensuring that operations run smoothly and efficiently.

Tips for maximizing productivity with your CNC machine include regular maintenance and updates to software. Keeping the machine in optimal condition prevents unexpected breakdowns and costly downtime. Moreover, investing in training for your operators can lead to better handling of the machine, ensuring that they fully exploit its capabilities. Familiarizing the staff with advanced features such as toolpath optimization can result in decreased cycle times and improved output quality.

Comparing different models reveals a clear trend: machines that utilize AI-driven analytics tend to exhibit greater improvements in productivity. These models can analyze machining patterns and suggest adjustments to enhance performance, making them a valuable asset for businesses aiming to stay competitive in the evolving manufacturing landscape. Embracing such technology ensures that operators can achieve the best possible results in their production processes.

The future of 3D CNC technology is poised to reshape the manufacturing landscape significantly, particularly with the anticipated growth in precision machining capabilities. As industries increasingly adopt advanced digital manufacturing techniques, productivity is expected to rise dramatically. Reports forecast that the global metal manufacturing products market will grow from approximately $653.6 billion in 2025 to an impressive $742.1 billion by 2033, indicating a compound annual growth rate of 1.6%. This rapid growth is driven by the demand for high-precision and efficient manufacturing processes, leading to a shift towards automated solutions that can meet these complex requirements.

Moreover, the shift towards environmentally friendly machines is becoming a crucial trend as manufacturers seek lower operational costs and sustainable practices. The integration of advanced CNC technologies yields not only enhanced productivity—potentially boosting it by 30%—but also aligns with global sustainability goals. According to investment research reports, utilizing external AI systems for cost analysis reveals that the pricing structures for metal 3D printing can significantly impact operational efficiency. This evolution in CNC technology and its associated cost dynamics will play a crucial role in the continued transformation of the production environment across various sectors.

© Copyrights Levil Technology Corp 2022