When choosing a 4 axis CNC mill, many factors come into play. According to John Smith, an industry expert and consultant, “The right mill can elevate your production capabilities significantly.” His insights help demystify the selection process. A 4 axis CNC mill offers advanced machining solutions, allowing flexibility and precision.

Understanding specific needs is vital. For instance, consider the materials you'll work with and the types of projects you will undertake. While efficiency matters, seeking a mill that suits your workflow is equally important. Sometimes, the most popular choice might not meet your unique requirements.

Budget is also a key factor. A high-quality 4 axis CNC mill can be a significant investment. However, finding balance between cost and capability often leads to better long-term results. It’s important to avoid choosing based solely on price. Each decision should stem from thoughtful consideration of your machining needs.

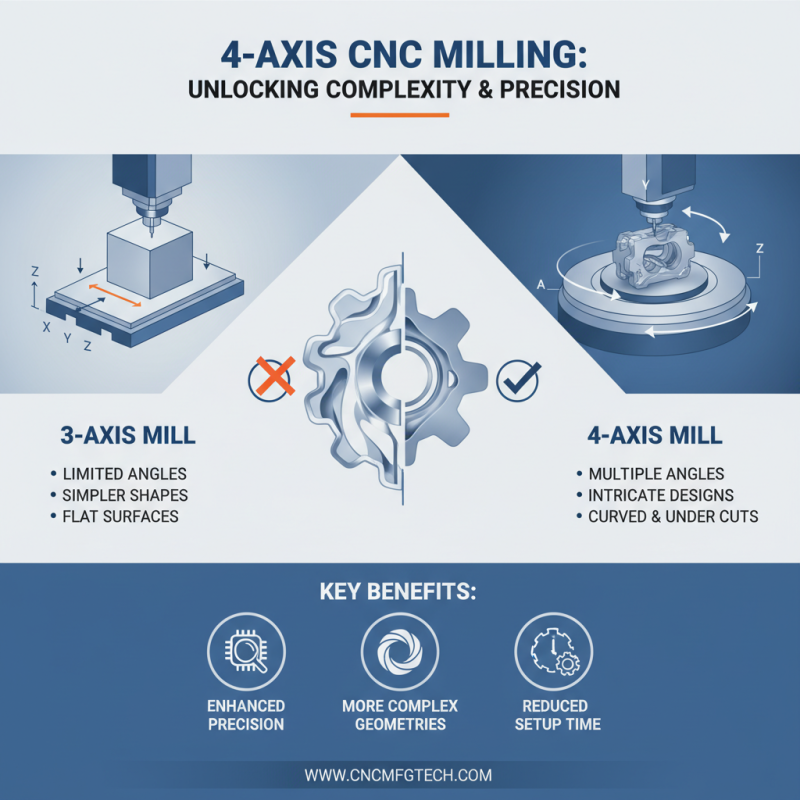

4-axis CNC milling technology broadens the capabilities of traditional machining. It allows for more complex designs and enhanced precision. The addition of a rotating axis enables cutting tools to approach the workpiece from various angles. This results in more intricate shapes that a 3-axis mill cannot produce.

When choosing a 4-axis CNC mill, consider the intended applications. What materials will you primarily work with? Soft metals like aluminum are easier to machine than harder materials. It’s vital to assess the machine’s rigidity and stability. Any vibration can affect precision and finish.

Some operators find it challenging to adapt to the added complexity. Learning to program a 4-axis machine is not straightforward. There might be a steep learning curve. Mistakes are common, especially with toolpath simulations. Testing different setups can lead to unexpected results. Each project may reveal new challenges, and reflecting on these experiences is crucial for growth.

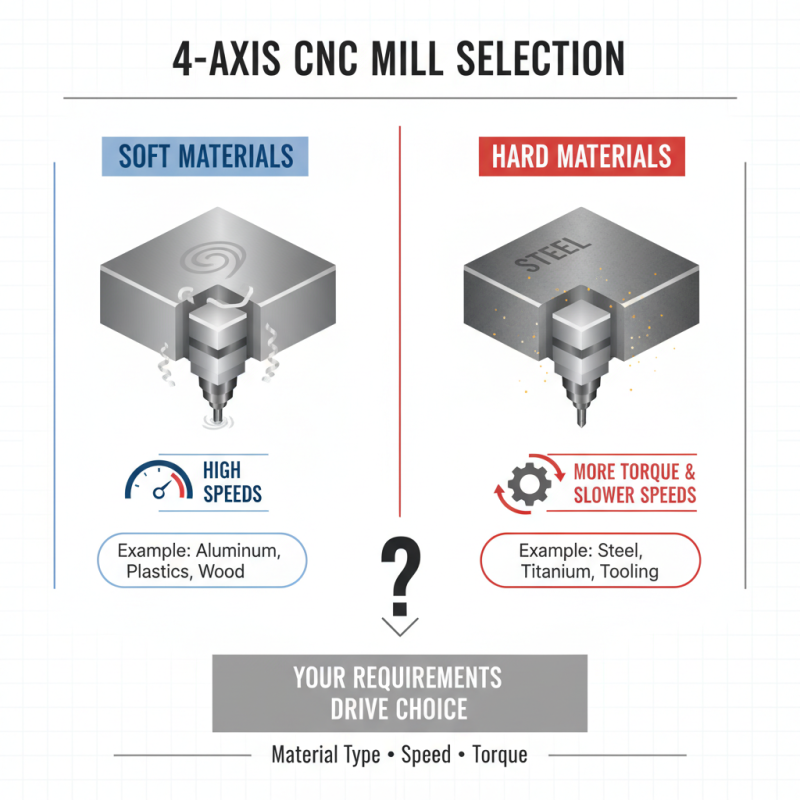

When choosing a 4-axis CNC mill, it's essential to identify your specific machining requirements. Think about the materials you work with. Are they soft, like aluminum, or harder materials, such as steel? This decision impacts the type of CNC mill needed. Soft materials allow higher speeds, while hard materials may require more torque and slower speeds.

Consider the size of your projects. A compact CNC mill might work for smaller tasks. Larger projects, however, demand a mill with an extended workspace. This choice influences efficiency and accuracy. Remember, larger doesn’t always mean better. Assess if you really need that extra space.

**Tips:**

- Structuring your workflow can save time. Plan your projects in advance.

- Experiment with different settings to find optimal results. Adjust speeds and feeds regularly.

- Look at the ease of programming. A user-friendly interface can improve productivity.

Choosing a 4-axis CNC mill requires careful consideration of key features. One major element is the machine's build quality. You want a rigid structure that minimizes vibrations. This ensures precision during machining. Look for solid construction materials. A well-built machine performs optimally, even under heavy loads.

Another important feature is the software compatibility. A user-friendly interface is essential. It should support various file formats for diverse projects. If the software is too complex, it can become frustrating. Ensure it matches your skill level and the tasks you intend to perform. Lastly, check for support and resources. Good customer service can save you time and headaches later.

Don't forget about the spindle speed and tool capacity. These affect efficiency and output quality. Make sure the mill accommodates the tools you need. A lack of flexibility can hinder production. Evaluate if you require extra features like automatic tool changers. While they enhance productivity, they may not be necessary for all users.

When choosing a 4-axis CNC mill, it's essential to consider brand reputation and customer support. A well-regarded brand often indicates reliability, but it's not the only factor. Reading customer reviews can provide insight into real-world performance. Some brands may have a stellar reputation but lack support for new users. This can lead to frustration when troubleshooting common issues.

Customer support options vary widely. Some manufacturers offer extensive resources, including manuals and online tutorials. Others have limited availability, which can be a major drawback. Consider reaching out to their support teams with questions. A prompt, helpful response usually indicates good service. Look for brands that have active forums or communities. Engaging with other users can often provide practical advice and solutions.

Evaluating support options remains critical. A brand might have an excellent reputation but poor customer service. It's important to reflect on your own needs, especially if you are a beginner. Think about whether you prefer instant assistance or self-service options. Sometimes, the best choice may not be the most recognized or praised brand, but one that aligns with your specific requirements and offers solid support.

When budgeting for a 4-axis CNC mill, consider both initial costs and long-term investments. The average entry-level 4-axis CNC mill costs between $30,000 and $60,000. This is a significant investment. Additional expenses include tooling, software, and maintenance. These can add up quickly, often reaching 20% of the initial purchase price. Setting a budget should not only cover the machine itself but also these ongoing costs.

Selecting the right CNC mill is essential for your projects. A mill’s capabilities affect production efficiency. According to industry reports, machines that offer higher accuracy and reliability tend to have lower operational costs in the long run. Businesses may prioritize lower initial costs over quality. However, this can lead to frequent repairs and downtime. A machine that is less expensive upfront may come with hidden costs, impacting profitability.

In addition to financial considerations, consider financing options. Many manufacturers offer financing to help manage costs. This can make a higher-quality mill more accessible. However, it's crucial to read the fine print. Some financing options may have high interest rates. Weigh all these factors carefully. They will determine the overall success of your machining operations.

| Feature | Description | Estimated Cost (USD) |

|---|---|---|

| Machine Type | 4 Axis CNC Mill | $20,000 - $40,000 |

| Spindle Speed | High-speed spindle for precision cutting | Included |

| Controller Type | CNC with user-friendly interface | $3,000 - $7,000 |

| Work Area Size | Typically ranges from 30" x 20" to 50" x 30" | Included |

| Software Compatibility | Compatible with various CAD/CAM software | $1,000 - $3,000 |

| Power Requirements | 220V, 3-phase power supply | Included |

© Copyrights Levil Technology Corp 2022