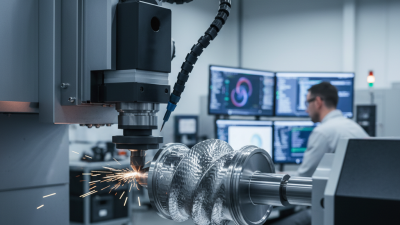

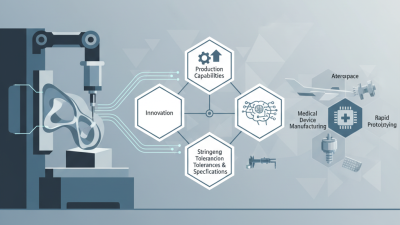

The demand for precision machining is rising. A recent survey by the Association for Manufacturing Technology indicates that 39% of manufacturers are investing in 5 axis CNC mills. These machines offer unparalleled capabilities. They perform complex tasks with high accuracy, making them essential for various industries. However, choosing the right model can be daunting.

When selecting a 5 axis CNC mill, several factors come into play. You must consider accuracy, ease of use, and software compatibility. Reports show that 72% of industry leaders prioritize these features. Additionally, analyzing the cost versus functionality is crucial. Some machines are costly but may not deliver the expected return on investment. This is a common pitfall.

Being informed is vital. Many businesses overlook maintenance and support options. This oversight could lead to increased downtime. Always assess the available customer service and technical support. Ultimately, the goal is to select a 5 axis CNC mill that meets your specific project needs while remaining viable for the long term. Reflection on your choices is essential in this rapidly evolving field.

5-axis CNC milling machines are revolutionary in modern manufacturing. These machines can move a tool or workpiece along five different axes simultaneously. This flexibility allows for the creation of complex shapes and intricate designs. Understanding the basics is crucial before diving into choosing a machine.

The core components include the spindle, bed, and control system. The spindle is vital for tool rotation. Bed size impacts workpiece dimensions. Control systems can be either manual or computer numerical controlled. CNC systems require programming knowledge. Many newcomers face challenges here. It's important to assess your skill level before committing.

When considering capabilities, think about material types. Some machines handle soft materials better than hard ones. Not all projects demand 5-axis capabilities. Sometimes, a simpler machine suffices. Reflecting on your specific needs helps prevent overspending. Explore your options thoroughly. A little homework goes a long way in making the right choice.

When selecting a 5 axis CNC mill, several factors come into play. First, consider the size and weight of your projects. A compact machine may work for small parts, but larger jobs require a more robust model. Think about your workspace too. Is there enough room for a hefty machine? A cluttered area can lead to accidents and poor results.

Next, evaluate the mill's precision. Tolerances are key in machining. Look for a model that offers tight tolerances for your specific application. How often will you need to change setups? A mill with quick-change capabilities can save you time and frustration. Maintenance is another critical factor. Some machines have easier access to parts. This will aid in routine checks and repairs.

Lastly, consider software compatibility. Your mill needs to work seamlessly with your design software. A mismatch can lead to wasted materials and lengthy adjustments. Investing time in understanding the machine’s interface is crucial. No one wants to face a learning curve in the middle of a project. Reflect on your needs carefully to avoid costly mistakes. Each decision shapes the outcome of your projects.

| Feature | Description | Importance |

|---|---|---|

| Work Envelope Size | The maximum size of the material that can be machined. | High |

| Precision | The accuracy of the movements and the quality of the finished product. | Critical |

| Spindle Speed | Max RPM of the spindle, affecting cutting speed and tool life. | Medium |

| Control System | User interface and software capabilities that affect usability. | High |

| Tool Changing System | Automated system for switching tools without manual intervention. | Medium |

| Price | Overall cost of the machine including maintenance and tooling. | High |

| Material Compatibility | Types of materials the mill can effectively work with. | High |

| Customer Support | Availability and quality of technical support from the manufacturer. | Medium |

When comparing different types of 5 axis CNC mills, it's crucial to consider their features. Some mills excel in speed, while others focus on precision. Speed can be beneficial for large-scale manufacturing, yet it may compromise surface finish. Precision is vital for intricate designs, but slower speeds can delay production times.

Additionally, various machines come with unique capabilities. Some have advanced software that enhances user experience. Others may offer better build quality but lack in sophisticated features. Choosing the right machine also depends on your specific projects. For instance, a high-end model might be more than needed for simpler tasks, leading to unnecessary expenses.

There's also the aspect of maintenance. More complex machines often require specialized knowledge to operate and fix. This can be a barrier for some users. Simple machines might actually offer more flexibility. Testing prototypes on different CNC mills can help reflect on what works best for your needs. Each project's demands can make one option preferable over another.

This chart compares different types of 5 Axis CNC Mills based on their capabilities and features that are essential for various projects.

When considering a 5-axis CNC mill, assessing your project requirements is crucial. Start by evaluating the materials you intend to work with. Different materials necessitate varying levels of tool strength and precision. For instance, metals like aluminum or brass demand robust tooling. Meanwhile, softer materials like plastics need less intense setups. This understanding can prevent tool wear and potential project failures.

Tip: Outline your project goals in detail. Know your dimensions and tolerances. This information helps narrow down machine options. If you require intricate designs, look for mills with advanced software capabilities. A user-friendly interface can streamline the programming process.

Pay attention to the complexity of your parts. Consider how many different angles you need to machine. An overly complex design may lead to errors or production delays. Factor in your skill level, too. Advanced machinery can be intimidating. If you're new, a simpler machine may better suit your needs.

Tip: Don’t hesitate to reach out to community forums. Engaging with experienced users can provide valuable insights. Ask specific questions about machine capabilities and common challenges. This can influence your final decision significantly.

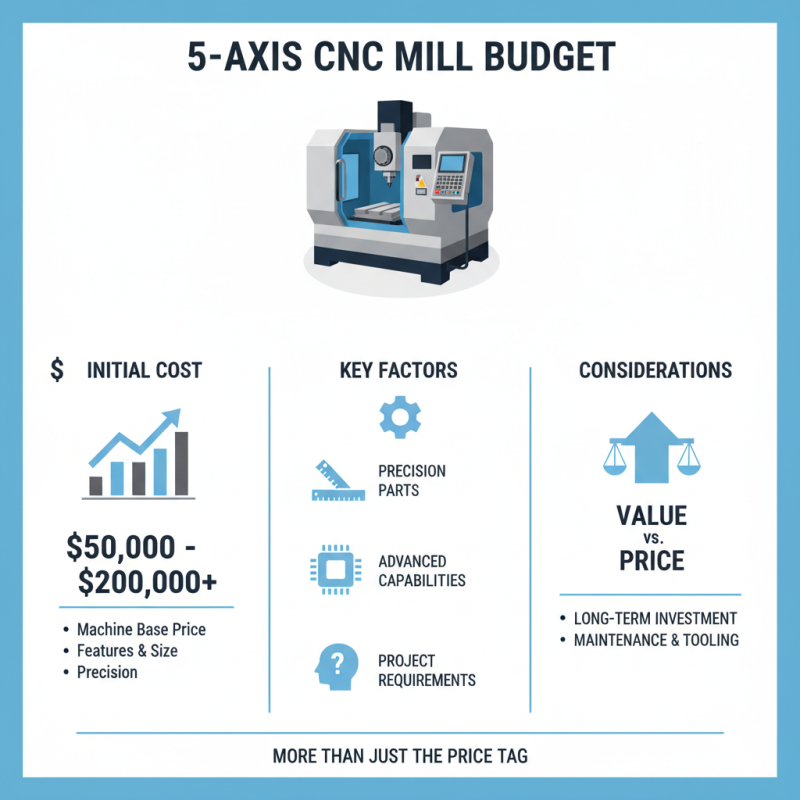

Budgeting for a 5-axis CNC mill can be a complex task. The initial cost of a quality machine often ranges from $50,000 to over $200,000. This price varies based on features, size, and precision. Many projects require precision parts, and high-end mills offer advanced capabilities. However, the decision should not rely solely on price.

Maintenance costs are another key factor. Annual maintenance can range from $5,000 to $15,000, depending on usage. Regular maintenance ensures longevity and performance accuracy. Furthermore, software costs for operating a 5-axis CNC mill can add $2,000 to $10,000. This is a critical piece often overlooked.

Considering these expenses is crucial for your overall budget. A study found that nearly 40% of businesses underestimated their CNC operating costs. This highlights the importance of thorough planning. Ask yourself about potential downtimes as well. A machine sitting idle for even a few days can spike costs. Proper budgeting leads to smarter investments and better project outcomes.

© Copyrights Levil Technology Corp 2022