When it comes to precision manufacturing and complex designs, the 4 axis CNC machine has become an invaluable tool for various industries. According to a recent industry report by Market Research Future, the demand for CNC machines, particularly 4 axis models, is expected to grow at a CAGR of 6.2% from 2021 to 2026. This growth is driven by advancements in technology and an increasing need for efficient and accurate machining processes across sectors such as aerospace, automotive, and medical devices.

Experts in the field emphasize the importance of understanding your project's specific requirements when selecting a 4 axis CNC machine. Dr. Emily Chen, a renowned expert in CNC machining technologies, stated, "Choosing the right 4 axis CNC machine can significantly impact the efficiency and quality of your production." Her insight underscores the necessity for stakeholders to assess features like axis configuration, software compatibility, and tooling options tailored to their unique operational needs. With a careful evaluation, manufacturers can ensure that they are equipped with the best machinery to optimize their workflows and enhance productivity.

When choosing a 4 axis CNC machine for your projects, it's crucial to first understand the basics of how these machines operate. A 4 axis CNC machine enhances traditional 3 axis systems by adding a rotating axis, typically referred to as the A-axis. This added rotation allows the tool or the workpiece to move not just in linear paths (X, Y, and Z axes), but also around one of these axes, enabling more complex shapes and contours to be machined with higher precision. This capability is particularly beneficial for creating intricate designs and detailed prototypes that would be challenging or impossible with a standard 3 axis machine.

Furthermore, the versatility of 4 axis machining allows for enhancements in productivity and efficiency. With the ability to approach a workpiece from multiple angles without needing to reposition the material, manufacturers can achieve significant time savings and reduce the risk of errors associated with manual adjustments. This multi-dimensional machining not only streamlines the workflow but also helps lower production costs over time by minimizing waste and machinery usage. Understanding these fundamentals will guide you in selecting the right 4 axis CNC machine that aligns with your specific project needs and manufacturing goals.

| Feature | Description | Importance |

|---|---|---|

| Axis Configuration | The number of axes determines the complexity of the machining process, with 4-axis machines allowing for more intricate designs. | High |

| Max Workpiece Size | Indicates the maximum dimensions of the material that can be machined. | Medium |

| Spindle Speed | The RPM at which the spindle rotates, affecting the machine’s ability to cut various materials effectively. | High |

| Control System | The software and hardware that govern machine operations, critical for precision and ease of use. | High |

| Price Range | The cost of the machine, which can vary widely based on features and capabilities. | Medium |

| Material Compatibility | Types of materials the machine can handle, such as metal, wood, or plastic. | High |

| Footprint | The physical space required for the machine, which is important for workshop layouts. | Medium |

| Support & Service | Availability of customer support and training for operation and troubleshooting. | High |

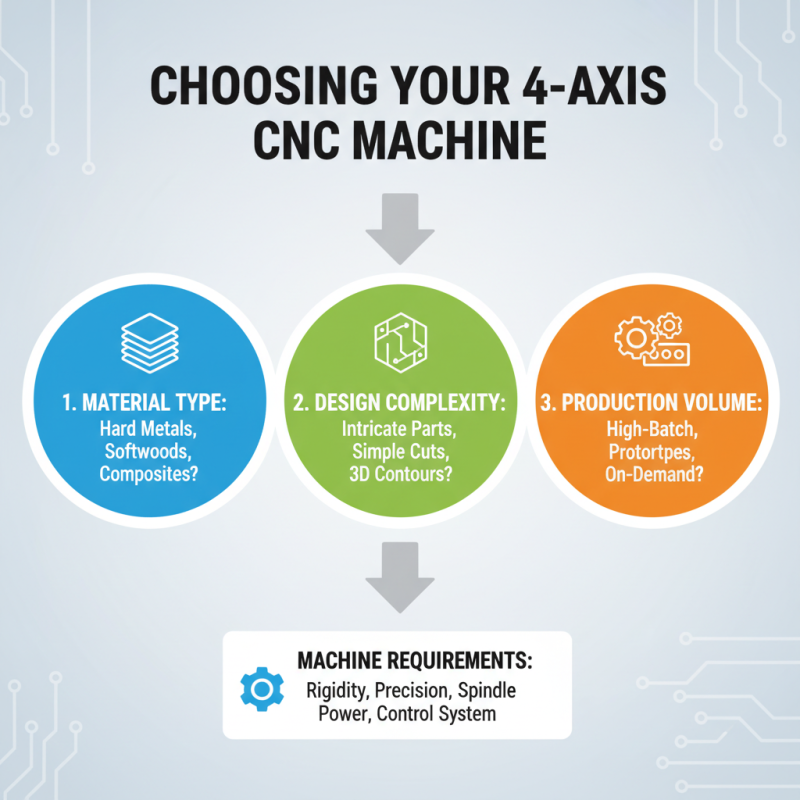

When selecting a 4-axis CNC machine, several key features should be evaluated to ensure it meets your project requirements. First and foremost, consider the machine's rigidity and build quality. A sturdy frame can absorb vibrations during operation, resulting in more precise cuts and enhanced durability. It is crucial to check if the machine incorporates high-quality components, such as linear guides and ball screws, which contribute to accuracy and longevity.

Another important aspect is the control system. A user-friendly interface facilitates ease of operation, particularly for complex projects. Examine the software compatibility with various file formats, as this can affect your workflow. Additionally, look for features such as tool compensation, probing capabilities, and the ability to handle diverse materials, as these can significantly expand the versatility and efficiency of your machining processes. Pay attention to the machine's travel dimensions and spindle speed options, as these specifications will directly influence the range of projects you can tackle.

When choosing the best 4 axis CNC machine for your projects, the first step is to clearly assess your project requirements. Understanding the specific materials you intend to work with, the complexity of the designs, and the expected volume of production are crucial. For example, if your projects involve machining intricate parts from hard metals, you’ll need a machine that can withstand rigorous use and provide precise control over the operational parameters.

Tips: Prior to making a purchase, create a list of the functionalities you need in your CNC machine. Consider factors such as the axis configuration, spindle power, and cutting speed. This will help you narrow down your options and find a machine that aligns with both your immediate and long-term project goals.

Another important aspect is to evaluate the capabilities of the machine based on its software compatibility and ease of use. A user-friendly interface can significantly reduce the learning curve, while advanced software can enhance your design and machining processes. Always look for machines that offer good support and resources for troubleshooting and upgrades.

Tips: Take time to read user reviews and test demos whenever possible. Engaging with a community of CNC users can provide insights into how well a machine performs in real-world applications, helping you make an informed decision.

When selecting a 4-axis CNC machine for your projects, evaluating budget and cost efficiency is crucial. The initial purchase price is often the first consideration, but it is essential to look beyond that.

Consider the machine's operational costs, including tooling, maintenance, and energy consumption. A more expensive CNC machine might offer advanced features or higher precision, which can ultimately lead to better product quality and reduced waste in the long run.

This means lower operational costs can offset the higher upfront cost, making it a more cost-efficient choice over time.

Additionally, think about the machine's versatility and potential for future projects. If a CNC machine can handle a variety of materials or perform multiple tasks, it may eliminate the need for additional equipment, further enhancing cost efficiency.

It's also important to factor in the reliability and vendor support, as these can reduce downtime and extend the life of the machine.

By thoroughly assessing these aspects, you can make a more informed decision that balances your budget constraints with the long-term value of your investment in a 4-axis CNC machine.

When choosing a 4-axis CNC machine, comparing popular brands and models can help you make an informed decision tailored to your specific needs. Each brand typically offers various models that cater to different levels of expertise, material compatibility, and project requirements. Some machines are designed for precision and intricate detailing, while others are better suited for large-scale projects or mass production. Investigating the specific features of each model, such as spindle speed, control software, and axis travel, is critical to ensuring the machine aligns with your intended applications.

Additionally, user reviews and expert recommendations can provide valuable insights into the reliability and performance of different CNC machines. Factors such as build quality, ease of use, and customer support can significantly influence your experience. By assessing the experiences of other users with similar projects, you can identify which machines excel in specific areas, such as ease of setup or maintenance requirements. Ultimately, finding a model that combines quality, performance, and suitable features will ensure the success of your CNC machining projects.

© Copyrights Levil Technology Corp 2022