In today's fast-paced industrial landscape, businesses are increasingly seeking efficient and innovative solutions to meet their production needs. One such solution that is gaining significant traction is CNC machine printing. This advanced technology combines the precision of computer numerical control with the versatility of printing, allowing businesses to produce high-quality, intricate designs with minimal waste and maximum efficiency. Whether it's for creating prototypes, custom parts, or large-scale production runs, CNC machine printing can offer unparalleled accuracy and consistency that traditional methods may struggle to achieve.

As competition intensifies across various sectors, the ability to rapidly adapt and produce unique products can be the key differentiator for businesses. CNC machine printing enables companies to streamline their manufacturing processes, reduce lead times, and enhance customization capabilities. This not only enhances operational efficiency but also enables businesses to respond swiftly to market demands and customer preferences. In a world where quality and precision are paramount, leveraging CNC machine printing can provide a competitive edge that is difficult to overlook. By choosing this technology, businesses can unlock new possibilities for innovation, ensuring they remain at the forefront of their industries.

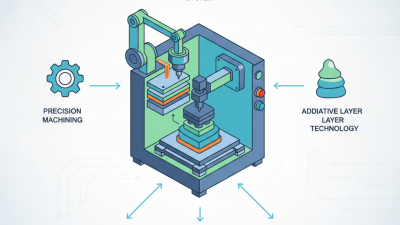

CNC machine printing, a sophisticated method of manufacturing, has become integral to various industries due to its precision and efficiency. This process employs computer numerical control technology to operate machinery, enabling the production of intricate designs and shapes with minimal human intervention. As reported by the International Journal of Advanced Manufacturing Technology, the adoption of CNC technology has led to a 30% increase in manufacturing efficiency and a significant reduction in waste, ultimately lowering production costs for businesses.

The versatility of CNC machine printing allows for the utilization of various materials including metals, plastics, and composites, catering to diverse industrial needs. According to a study by the Research and Markets report, the global CNC machine market is projected to grow from $81 billion in 2021 to over $114 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.3%. This growth emphasizes the increasing reliance of businesses on CNC technology for enhanced performance, customization options, and scalability, enabling companies to meet evolving customer demands more effectively. With the ongoing advancements in software and hardware, CNC machine printing is expected to further transform industrial production capabilities in the years to come.

CNC machine printing has emerged as a preferred choice for businesses aiming to enhance production efficiency and precision. One of the most significant advantages of CNC machine printing lies in its ability to provide unparalleled accuracy. According to a report by the International Journal of Advanced Manufacturing Technology, CNC machining technologies can achieve tolerances as tight as ±0.005 mm. This level of precision is crucial for sectors such as aerospace and automotive, where even the smallest error can lead to significant operational failures or safety issues.

Another key benefit is the scalability of CNC machine printing. As businesses evolve, the ability to quickly adapt to new designs and production requirements is essential. A study by the National Institute of Standards and Technology highlighted that companies implementing CNC technology have seen a reduction in production lead times by up to 40%. This adaptability not only minimizes downtime but also significantly lowers production costs, allowing businesses to remain competitive in a rapidly changing market.

Furthermore, CNC machine printing enhances productivity through automation, reducing the need for manual intervention. According to the National Center for Manufacturing Sciences, businesses that utilize CNC machines report a productivity increase of approximately 50% compared to traditional machining methods. This increase in efficiency translates to higher output and faster turnaround times, making CNC machine printing a strategic investment for businesses looking to optimize their manufacturing processes.

CNC machine printing has revolutionized various industries by offering precise and efficient production methods. From manufacturing to healthcare, the applications of CNC machine printing are vast and varied. In the automotive industry, for instance, CNC technology enables the creation of intricate parts with exact specifications, improving both performance and safety. Similarly, in the aerospace sector, it allows for the production of lightweight components, thus enhancing fuel efficiency without compromising structural integrity.

In the healthcare field, CNC machine printing is utilized for producing customized prosthetics and implants that perfectly fit individual patients, significantly improving comfort and functionality. It also plays a role in the production of medical devices, ensuring they meet strict quality standards through consistent and repeatable manufacturing processes. The versatility of CNC machines means that they can be adapted for use in almost any industry, from woodworking to electronics.

Tip: When considering CNC machine printing for your business, assess your specific needs carefully. Identify areas where precision and customization are paramount to maximize the benefits of this technology. Furthermore, investing in skilled operators can greatly enhance the efficiency of your production processes. By staying informed about advancements in CNC technology, businesses can better innovate and stay competitive in their respective fields.

CNC machine printing has emerged as a powerful alternative to traditional printing methods, offering distinct advantages that cater to the evolving needs of businesses. Unlike conventional printing techniques, which often rely on labor-intensive processes and can produce inconsistent results, CNC machine printing harnesses the precision of computer-controlled systems. This technology enables high-volume production with remarkable accuracy, allowing intricate designs and complex geometries to be executed with ease. As a result, businesses can achieve higher quality outputs while minimizing waste and streamlining their workflow.

Additionally, CNC machine printing significantly reduces turnaround times compared to traditional methods. Traditional printing can be hampered by setup times and material limitations, which can delay project completion. In contrast, CNC machines can quickly switch between designs and materials, making them ideal for operations that require flexibility and efficiency. With the capability to operate continuously and minimize downtime, businesses can respond more rapidly to market demands and customer requests, ensuring they stay competitive in a fast-paced environment. Overall, the shift towards CNC machine printing marks a significant evolution in the printing industry, facilitating innovation and efficiency for modern business needs.

| Feature | CNC Machine Printing | Traditional Printing Methods |

|---|---|---|

| Speed of Production | High | Moderate |

| Setup Costs | Higher Initial Investment | Lower Initial Investment |

| Material Versatility | Wide Range | Limited |

| Precision | Very High | Variable |

| Design Flexibility | Highly Flexible | Less Flexible |

| Color Accuracy | Excellent | Good |

| Environment Impact | Lower Waste | Higher Waste |

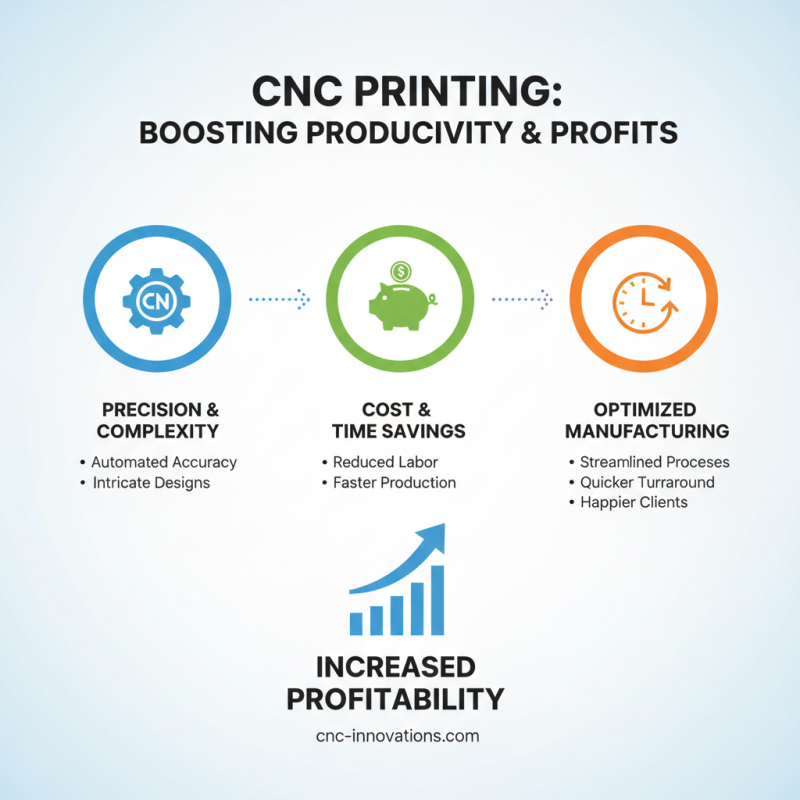

CNC machine printing has emerged as a pivotal solution for businesses seeking to enhance their productivity while maintaining cost-effectiveness. By utilizing computer numerical control technology, CNC printers can produce highly accurate and intricate designs with minimal manual intervention. This not only reduces labor costs but also significantly cuts down on the time required for production. As a result, companies can streamline their manufacturing processes, enabling faster turnaround times for clients and ultimately improving customer satisfaction.

Moreover, the initial investment in CNC machine printing equipment is often offset by the long-term savings it provides. With lower material waste and the ability to run production in larger batches, businesses can achieve greater economies of scale. The precision of CNC printing minimizes errors, thereby reducing the costs associated with rework and scrap materials. This combination of efficiency and cost-effectiveness makes CNC machine printing an ideal choice for businesses looking to compete in today’s fast-paced market while keeping operational expenses manageable.

© Copyrights Levil Technology Corp 2022