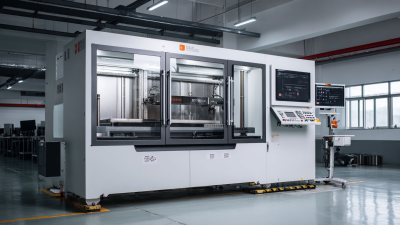

In today's fast-paced manufacturing landscape, the selection of the right CNC machining centers is crucial for unlocking efficiency and achieving optimal productivity within your business. CNC machining centers have revolutionized the way components are produced, offering precision, flexibility, and the ability to handle complex designs with ease. However, with a myriad of options available on the market, making an informed decision can be daunting. This introduction aims to guide businesses in understanding the various types of CNC machining centers and their features, enabling them to choose the most suitable machines that align with their operational needs. By examining factors such as capacity, speed, and versatility, companies can ensure they invest in equipment that not only enhances their manufacturing processes but also drives growth and innovation.

When selecting the appropriate CNC machining center for your business, several key factors must be considered to unlock operational efficiency. First, it's crucial to assess the specific requirements of your production needs. This includes understanding the types of materials you'll be working with, the volume of production, and the precision needed for your projects. A machining center that aligns with these requirements will not only enhance productivity but also ensure the quality of the final products.

Another significant aspect is the machine's capability in terms of size and tooling options. Consider the work envelope dimensions—this will determine the size of the components you can effectively manufacture. Additionally, evaluate the tool changers and the number of tools the machine can accommodate, as this affects setup times and, ultimately, throughput. Lastly, don't overlook the importance of software compatibility and support, as these can greatly influence the efficiency of your operations and the ease with which your team can utilize the machinery. By carefully analyzing these key factors, businesses can make informed decisions that lead to improved manufacturing processes and increased profitability.

When choosing the right CNC machining centers for your business, it's crucial to understand the different types available and their specific applications. CNC machining centers, such as milling, turning, and grinding machines, each serve distinct purposes within the manufacturing workflow. For instance, milling machines are ideal for creating precise shapes and features, while turning machines excel in producing symmetrical parts. As the market for CNC machines is projected to grow significantly, understanding these distinctions will help businesses leverage the best tools for their production needs.

Here are some tips for selecting the right CNC machining center: First, assess your production requirements—determine the types of materials you will be working with and the complexity of the parts needed. Second, consider the level of automation that suits your operations. With advancements in technology, options like 5-axis machining centers offer enhanced flexibility and efficiency, catering to complex geometries with ease. Lastly, factor in the service and support provided by manufacturers, as having access to expert assistance can significantly impact your operational success and maintenance routines. By prioritizing these aspects, companies can optimize their CNC machining capabilities and enhance overall efficiency.

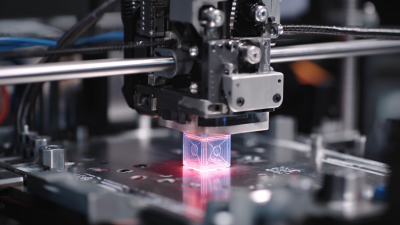

When selecting the right CNC machining centers for your business, evaluating technical specifications is crucial for optimizing performance and ensuring operational efficiency. Key specifications such as spindle speed, feed rate, and precision directly influence the machining processes. A report from the International Federation of Robotics indicates that CNC machines with spindle speeds exceeding 15,000 RPM can reduce production time by up to 30%, making them essential for high-volume manufacturing environments.

Moreover, considering the type of control system can significantly impact usability and integration into existing workflows. Advanced CNC centers often feature adaptive control technologies that enhance machining accuracy and reduce waste, leading to cost savings. According to a study by the Manufacturing Technology Association, incorporating state-of-the-art CNC technology has been shown to improve production efficiency by 25% in machining applications. Therefore, businesses must carefully analyze these technical specifications to ensure they choose CNC systems that align with their operational goals and production demands.

| Specification | Value | Importance |

|---|---|---|

| Spindle Speed | 10,000 RPM | High-speed machining and efficiency |

| Travel Range (X, Y, Z) | 1000mm x 600mm x 500mm | Versatile for various part sizes |

| Controller Type | Fanuc 0i-Mate | Ease of programming and operation |

| Tool Changes | Automatic, 24 tools | Reduced downtime between operations |

| Machine Dimensions | 3000mm x 2000mm x 2500mm | Saves space in production area |

| Weight | 2500 kg | Stability and precision during operation |

| Power Supply | 220V, 3-phase | Compatible with standard facilities |

When selecting the right CNC machining centers for your business, a thorough cost-benefit analysis is crucial. This process allows you to balance the features and price, ensuring that you invest wisely. A recent study on cost-benefit analysis highlights that organizations using this method can enhance productivity while limiting financial risk—something especially relevant in the competitive manufacturing sector. Companies that prioritize such analytical frameworks are more likely to see marked improvements in operational efficiency, similar to findings in employee health initiatives that correlate well-being with reduced absenteeism and overall productivity gains.

**Tips for Choosing CNC Machining Centers:**

First, assess your production needs and scalability. The right CNC machine should not only meet current demands but also accommodate potential future growth. Reports indicate that businesses looking to optimize their operations must consider both short-term costs and long-term benefits, which can drastically impact profitability over time.

Secondly, evaluate the total cost of ownership (TCO). This includes initial purchase price, maintenance, and operational costs. Industry insights suggest that a well-rounded approach to comparing TCO can illuminate which machines offer true value, with some high upfront cost options proving more cost-effective in the long run due to their durability and efficiency.

When choosing the right CNC machining centers for your business, future growth and scalability should be at the forefront of your decision-making process. As industries evolve, the demand for advanced machining capabilities continues to rise, driving a significant increase in market size. For instance, projections indicate that the global CNC machining market will grow from $22.22 billion in 2025 to $91.92 billion by 2032, reflecting a compound annual growth rate (CAGR) of 22.5%. This kind of growth underscores the necessity of selecting equipment that not only meets present requirements but also accommodates future demands.

Additionally, as businesses increasingly integrate technologies like AI and automated systems, it’s imperative to consider how well the chosen CNC machining centers can adapt to these innovations. Solutions that offer modularity and compatibility with emerging technologies will enable businesses to scale efficiently without incurring excessive costs. By prioritizing scalability, companies can ensure that their machining capabilities grow in tandem with market trends, thereby enhancing overall operational efficiency and competitiveness in an ever-changing landscape.

This chart displays the evaluation of various CNC machining centers based on key efficiency factors. The data demonstrates how different attributes such as speed, accuracy, and cost impact the decision-making process for businesses looking to invest in CNC technology.

© Copyrights Levil Technology Corp 2022