Exploring Varied Features and Applications of the Best Quick Mold Change Systems: A Comprehensive Guide

In the fast-paced world of manufacturing, efficiency and adaptability are paramount. One of the key innovations that has emerged to meet these demands is the Quick Mold Change System. This technology significantly reduces downtime during production by enabling rapid and efficient mold swaps, thereby optimizing workflow and increasing productivity.

As industries strive to enhance operational performance and meet diverse consumer needs, understanding the varied features and applications of Quick Mold Change Systems becomes essential. This comprehensive guide delves into the intricacies of these systems, exploring their benefits, implementation strategies, and the impact they have on manufacturing processes across different sectors.

Whether you're a seasoned professional or new to the industry, this guide will provide valuable insights into making informed decisions about adopting Quick Mold Change Systems in your facilities.

As industries strive to enhance operational performance and meet diverse consumer needs, understanding the varied features and applications of Quick Mold Change Systems becomes essential. This comprehensive guide delves into the intricacies of these systems, exploring their benefits, implementation strategies, and the impact they have on manufacturing processes across different sectors.

Whether you're a seasoned professional or new to the industry, this guide will provide valuable insights into making informed decisions about adopting Quick Mold Change Systems in your facilities.

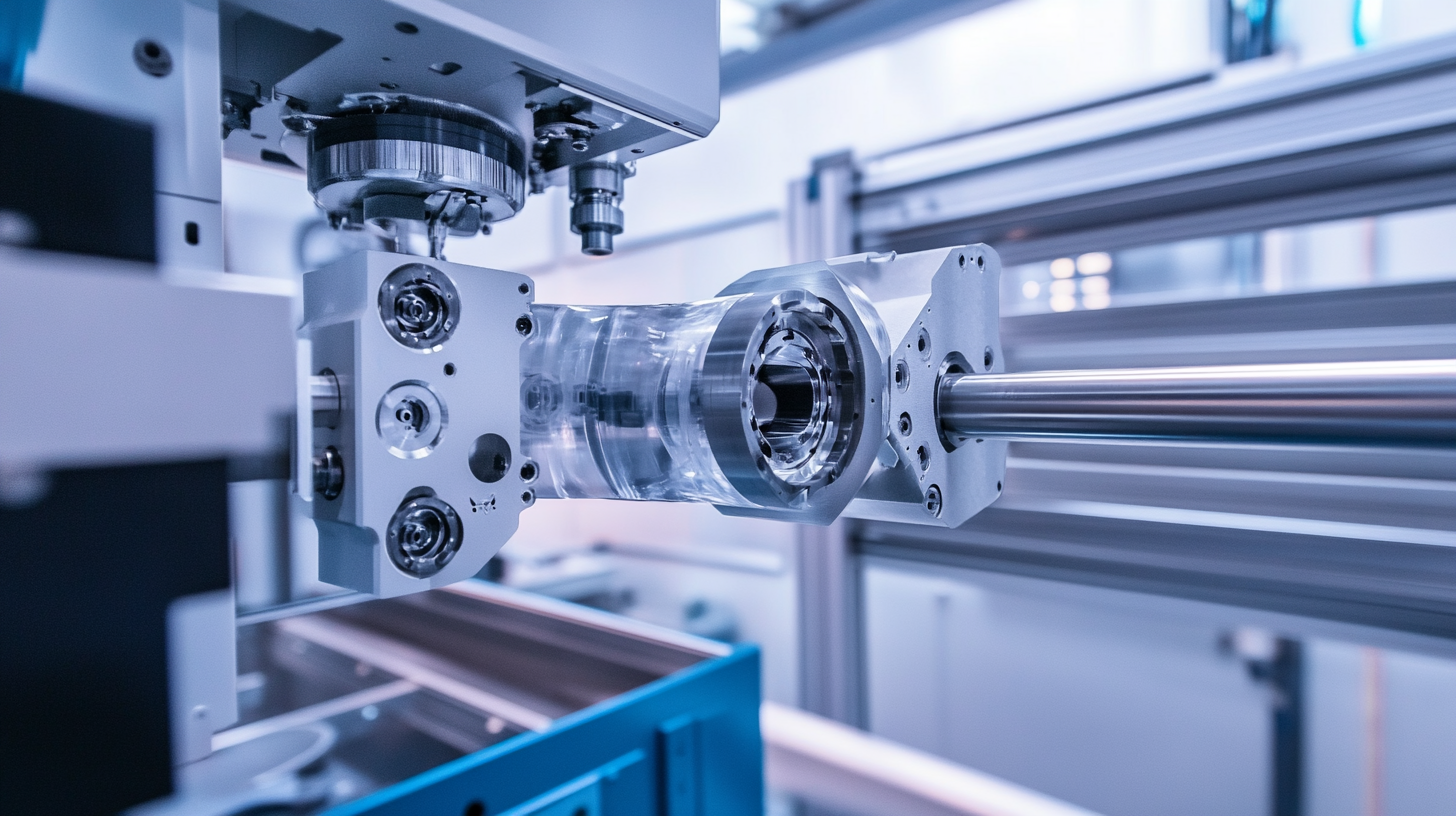

Understanding Quick Mold Change Systems: Key Components and Technologies

Quick Mold Change (QMC) systems have emerged as a pivotal technology in the injection molding sector, primarily aimed at enhancing operational efficiency and reducing downtime. The increasing complexity of product designs and the demand for higher quality parts necessitate a streamlined molding process. Recent developments highlight how innovative QMC solutions, such as magnetic mold clamping technologies, are capable of calculating the requisite clamping force for each mold in advance. This not only optimizes the changeover process but also enhances worker safety by minimizing manual handling.

Moreover, with the introduction of advanced systems designed for quick adjustments in shot sizes and color changes, manufacturers can respond swiftly to market demands. Data indicate that optimizing product changeover times can lead to substantial productivity gains, often cited as reducing cycle times by as much as 30%. As the industry faces pressure for quicker turnarounds and more varied product offerings, the implementation of state-of-the-art QMC systems becomes essential. The integration of Industry 4.0 methodologies further reinforces these advancements, allowing for smarter, data-driven manufacturing processes that align closely with the ever-evolving demands of the market.

Exploring Varied Features and Applications of the Best Quick Mold Change Systems

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| Modular Design | Allows for flexible configuration and easy integration. | Customizable for various mold types, improved efficiency. | Injection molding, die casting. |

| Automated Systems | Automated handling processes for faster changeovers. | Minimized downtime, increased productivity. | High-volume manufacturing. |

| Quick Release Mechanism | Mechanism for rapid disconnection and connection of molds. | Significantly reduces swap time. | Injection molding, stamping. |

| Interlocking Systems | Mechanisms that ensure proper alignment of molds. | Enhanced stability and precision. | Plastic injection, blow molding. |

| Integrated Sensors | Sensors that monitor the mold change process. | Real-time data for process optimization. | Automotive and electronics manufacturing. |

The Advantages of Quick Mold Change Systems in Modern Manufacturing

Quick mold change systems (QMCS) have become essential in modern manufacturing, offering numerous advantages that streamline production processes. One of the primary benefits is significant time savings. Traditional mold change procedures can take hours, often leading to production delays and increased costs.

With QMCS, manufacturers can reduce mold change times to mere minutes, allowing for more efficient scheduling and increased machine utilization. This rapid turnover not only enhances productivity but also enables companies to respond quickly to changing market demands.

Moreover, the precision and reliability of quick mold change systems minimize the risk of errors during the changeover process. By employing standardized interfaces and automated systems, manufacturers can ensure that molds are correctly aligned and securely fastened, reducing the likelihood of defects in the final product. This improved consistency leads to higher quality outputs and greater customer satisfaction. Additionally, the integration of quick mold change systems fosters flexibility in production, making it easier to switch between different products or variants without significant downtime. This adaptability is vital in today’s fast-paced manufacturing environment, where the ability to pivot efficiently can provide a competitive edge.

Comparative Analysis: Top Quick Mold Change Systems in the Market

In today's rapidly evolving manufacturing landscape, the significance of quick mold change systems cannot be overstated. These systems dramatically reduce the downtime associated with switching molds in injection molding and other manufacturing processes. As industries strive for efficiency, a comparative analysis of the top systems on the market reveals various innovative features designed to enhance productivity and minimize changeover time. Factors such as automation capabilities, ease of use, and compatibility with existing machinery play crucial roles in determining the best fit for specific manufacturing environments.

While exploring these quick mold change systems, it’s essential to consider the underlying economic forces that drive their adoption. Just as the food delivery ecosystem has adapted to meet consumer demands for speed and convenience, manufacturers are equally compelled to streamline operations in an increasingly competitive marketplace. Advanced technologies, such as automated clamping and real-time monitoring, are becoming standard. Businesses that understand these trends and implement an efficient quick mold change system will not only improve their operational efficiency but also gain a significant edge in the market.

Real-World Applications: Industries Benefiting from Quick Mold Change Solutions

In today's competitive manufacturing landscape, industries are increasingly turning to quick mold change solutions to enhance efficiency and reduce downtime. Automotive, consumer goods, and medical device sectors are among those reaping significant benefits. These systems streamline the production process by enabling rapid swapping of molds, thus allowing for quicker product changeovers. This versatility results in reduced lead times and increased product flexibility, which is crucial in fast-paced markets.

In today's competitive manufacturing landscape, industries are increasingly turning to quick mold change solutions to enhance efficiency and reduce downtime. Automotive, consumer goods, and medical device sectors are among those reaping significant benefits. These systems streamline the production process by enabling rapid swapping of molds, thus allowing for quicker product changeovers. This versatility results in reduced lead times and increased product flexibility, which is crucial in fast-paced markets.

Tip: To maximize the advantages of quick mold change systems, it's essential to invest in training your staff on these technologies. A well-trained team can ensure smoother transitions and minimize the potential for errors during the mold change process.

Furthermore, industries such as packaging and electronics also rely heavily on these systems. With ever-changing customer demands and customization, the ability to switch molds efficiently is key. Organizations benefit not just from improved turnaround times but also from lower labor costs associated with prolonged setups.

Tip: Regular maintenance of quick mold change systems is vital for optimal performance. Establishing a routine check-up schedule can prevent unexpected breakdowns and extend the lifespan of your equipment, ultimately saving costs in the long run.

Future Trends: Innovations Shaping the Evolution of Quick Mold Change Systems

The landscape of quick mold change systems is rapidly evolving, driven by technological advancements and the search for operational efficiency in manufacturing. Future trends indicate a significant shift towards automation and smart technologies. For instance, the integration of IoT (Internet of Things) capabilities within these systems allows for real-time monitoring and data collection, enabling manufacturers to optimize mold change processes and reduce downtime effectively. With predictive analytics, companies can forecast maintenance needs and avoid costly interruptions, enhancing overall productivity.

Moreover, the development of modular designs is shaping the future of quick mold change systems. These innovations allow for greater customization and flexibility, enabling manufacturers to easily adapt their setups for different production runs. This is particularly beneficial for businesses looking to respond quickly to market demands without extensive downtime for mold swapping. As industries embrace sustainability, the push for energy-efficient systems will also influence future designs, ensuring that quick mold change systems contribute to reduced waste and lower energy consumption while maintaining high performance.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी