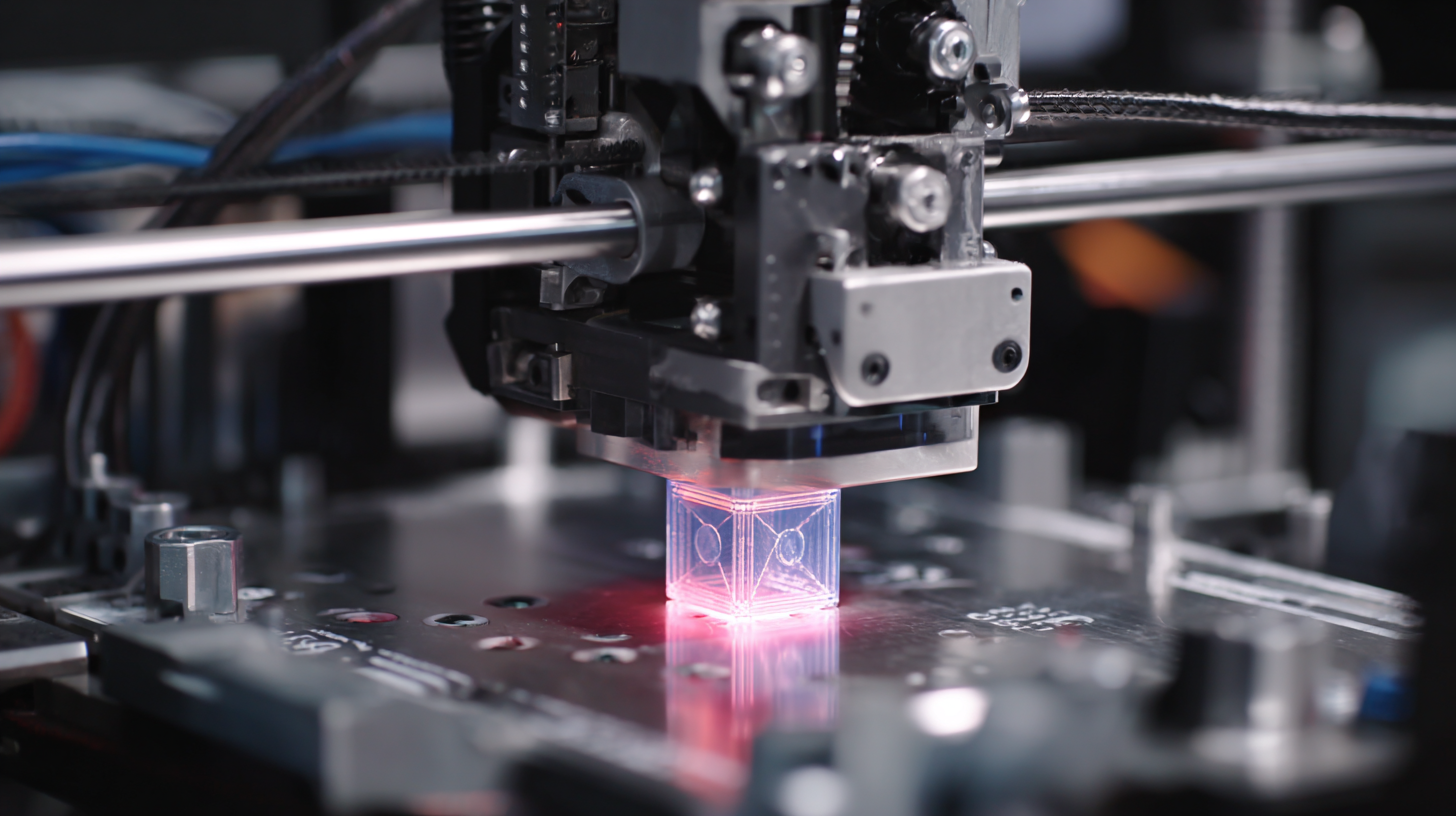

The advent of 3D printing technology is heralding a new era in manufacturing, one that promises to transform the way we design and produce goods. As industries across the globe begin to embrace this innovative process, a myriad of possibilities arise, enabling manufacturers to create complex structures with unprecedented precision and efficiency. This article explores the implications of 3D printing for the future of manufacturing, focusing on its ability to reduce waste, lower production costs, and cut lead times. By leveraging 3D printing techniques, companies are not only enhancing their operational capabilities but also fostering sustainability and customization, making it a pivotal player in the ongoing evolution of the manufacturing landscape.

As we delve into how this technology is reshaping traditional practices, we will uncover the potential it holds for driving innovation and meeting the demands of a rapidly changing market.

3D printing technology, also known as additive manufacturing, is transforming the landscape of modern manufacturing by enabling the rapid production of complex designs with minimal waste. As industries embrace this technology, understanding its fundamentals is crucial. According to a recent report by a leading market research firm, the global 3D printing market is expected to reach $34.8 billion by 2024, growing at a compound annual growth rate (CAGR) of 25.76%. This rapid expansion highlights how 3D printing is not just a trend but a significant evolution in manufacturing processes.

One of the key advantages of 3D printing is its ability to reduce production lead times. Traditional manufacturing methods often require weeks or even months for prototyping and production. In contrast, 3D printing can create prototypes within hours, allowing businesses to innovate quicker and bring products to market faster. This shift is evident in various sectors, from aerospace to healthcare, where customization and rapid iteration are critical.

Tips: To fully leverage 3D printing technology, businesses should invest in training their workforce and exploring partnerships with specialized 3D printing firms. Additionally, staying updated with advancements in materials and software will further enhance production capabilities and product quality, ensuring a competitive edge in the ever-evolving manufacturing landscape.

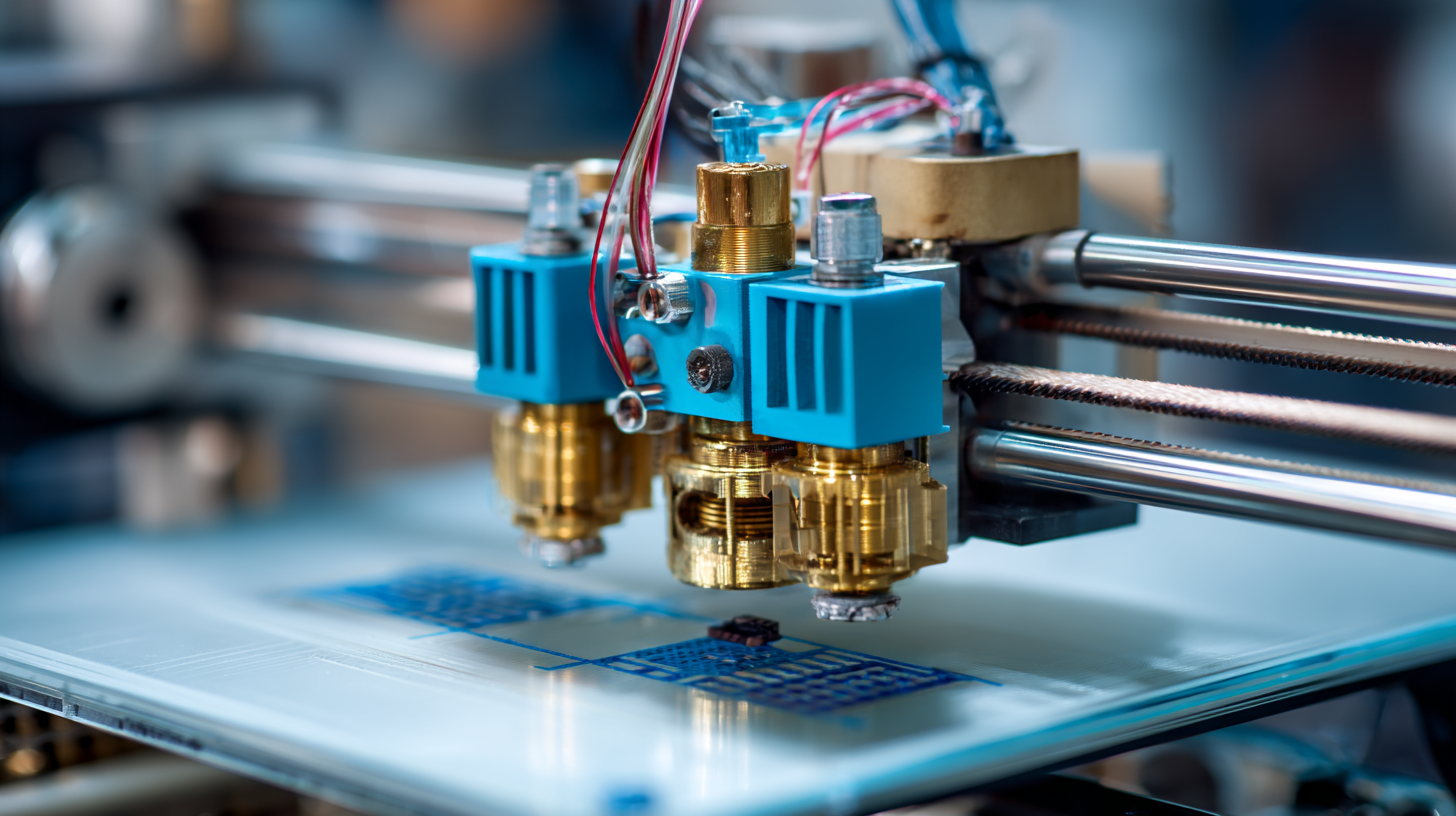

The transformation brought by 3D printing technology is profoundly reshaping various industries, notably manufacturing, healthcare, and food. In the manufacturing sector, the ability to create complex geometries and customized parts is gaining traction. According to a report by CBNData, companies are increasingly adopting 3D printing for prototyping and production, leading to a projected growth rate of over 25% annually in the coming years. This technology not only reduces production costs but also significantly shortens lead times, allowing businesses to respond to market demands swiftly.

The healthcare industry is experiencing a similar revolution, particularly in dental applications. Recent reports indicate that the dental sector is on the verge of a major shift, with advanced 3D printing technologies now capable of producing highly accurate dental prosthetics and aligners at scale. This trend was highlighted at a recent dental expo, where innovative printing solutions showcased the potential to enhance patient outcomes while streamlining production processes. As such, 3D printing is proving to be a pivotal force across multiple sectors, demonstrating its versatility and impact on future manufacturing practices.

3D printing technology is rapidly transforming the landscape of manufacturing, evidenced by the projected growth of the SLS 3D printer market, which is expected to expand from $1.353 billion in 2023 to $2.8118 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.5%. This significant growth underscores the economic impact of 3D printing, as it not only reduces production costs but also accelerates design iteration and increases customization options. Manufacturers can leverage 3D printing to create complex structures and reduce material waste, contributing to sustainable practices.

The shift towards additive manufacturing aligns with initiatives such as "Made in China 2025", which aims to upgrade the industrial capability of China by enhancing innovation and facilitating the transformation to a high-tech manufacturing hub. In the context of the broader economic framework, innovative manufacturing practices, including smart manufacturing and service-oriented manufacturing, are vital for achieving high-quality growth. Reports indicate that the intelligent manufacturing market in the U.S. alone is anticipated to grow from $66.18 billion in 2023 to $145.57 billion by 2030, at a CAGR of 11.9%. This surge illustrates how 3D printing, as a key component of modern manufacturing, is reshaping economic landscapes globally.

The integration of 3D printing technology in manufacturing presents various challenges that need to be addressed for successful implementation. One prominent issue is the high initial investment required for advanced 3D printing equipment and the materials needed. Organizations often face budget constraints, hindering their ability to adopt these innovative solutions. Additionally, there is a steep learning curve associated with operating and maintaining sophisticated 3D printing systems, which necessitates proper training and skilled personnel to optimize production processes.

Another significant challenge lies in ensuring the quality and reliability of 3D printed products. Manufacturers must establish rigorous quality control measures to meet industry standards. This involves developing robust testing methodologies to assess the mechanical properties of 3D printed components and addressing potential safety concerns in sectors such as medical devices. Furthermore, incompatibilities between traditional manufacturing techniques and 3D printing processes can complicate integration, requiring companies to reevaluate and adapt their existing workflows to accommodate this transformative technology.

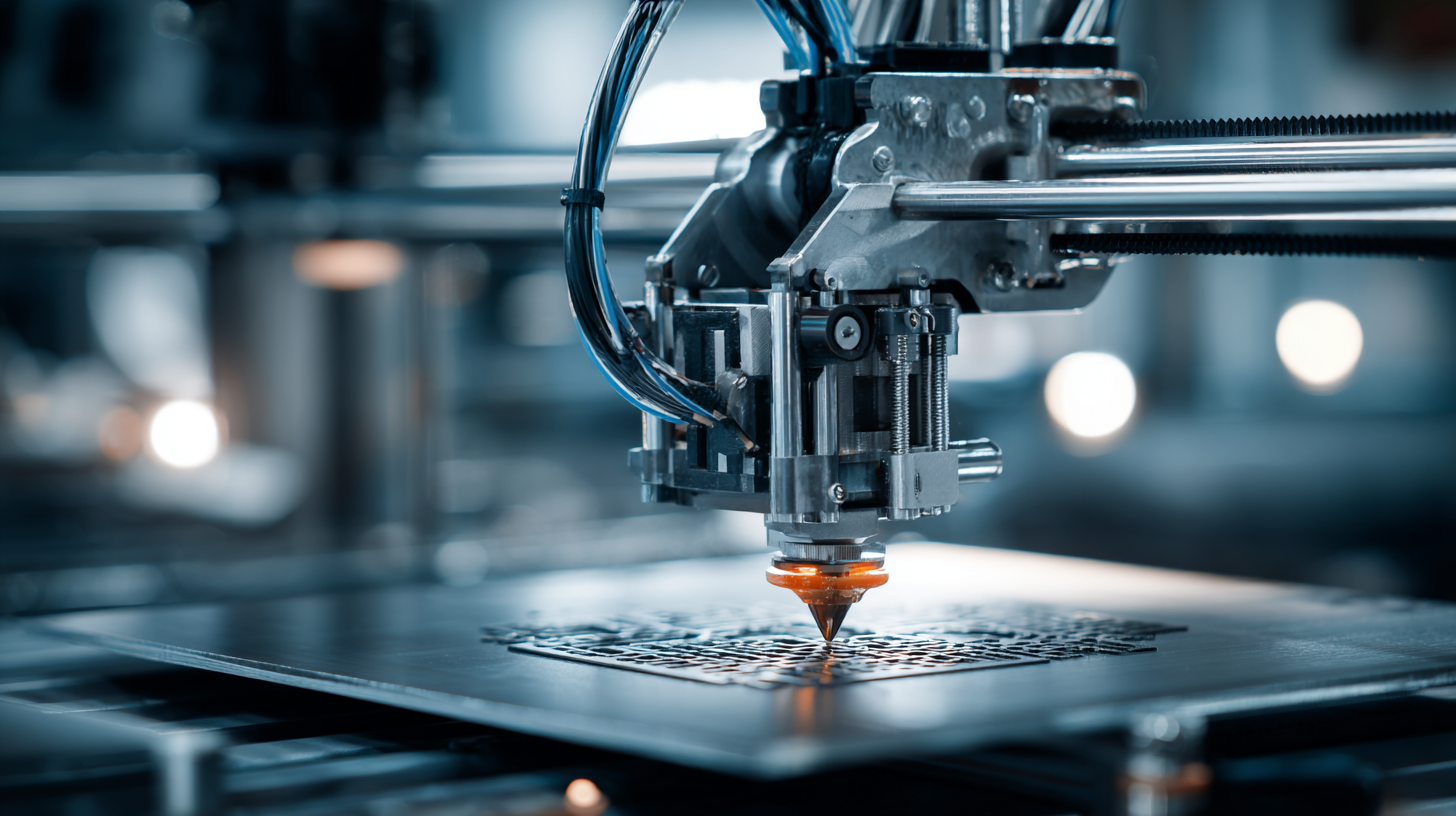

The landscape of 3D printing technology is experiencing a profound transformation driven by innovation and emerging trends. According to the latest "Technology Trends 2024" report, companies are encouraged to view 3D printing not as an isolated technology but as part of a broader ecosystem of advancements including generative AI and sustainable manufacturing practices. This strategic perspective is crucial for maintaining a holistic understanding of technological integration that can accelerate operational efficiencies and product design.

As we look forward to 2025 and beyond, market analysis indicates a remarkable expansion in the desktop 3D printing sector, projected to grow from $3 billion in 2023 to approximately $9.5 billion by 2032, with a compound annual growth rate (CAGR) of around 13.65%. Events like the upcoming 2026 Formnext Asia in Shenzhen highlight the rapid development within the industry, gathering experts to explore cutting-edge innovations. This surge illustrates how companies can leverage 3D printing to revolutionize their manufacturing processes while staying agile in a dynamic market landscape marked by consumer demand for customization and efficiency.

© Copyrights Levil Technology Corp 2022