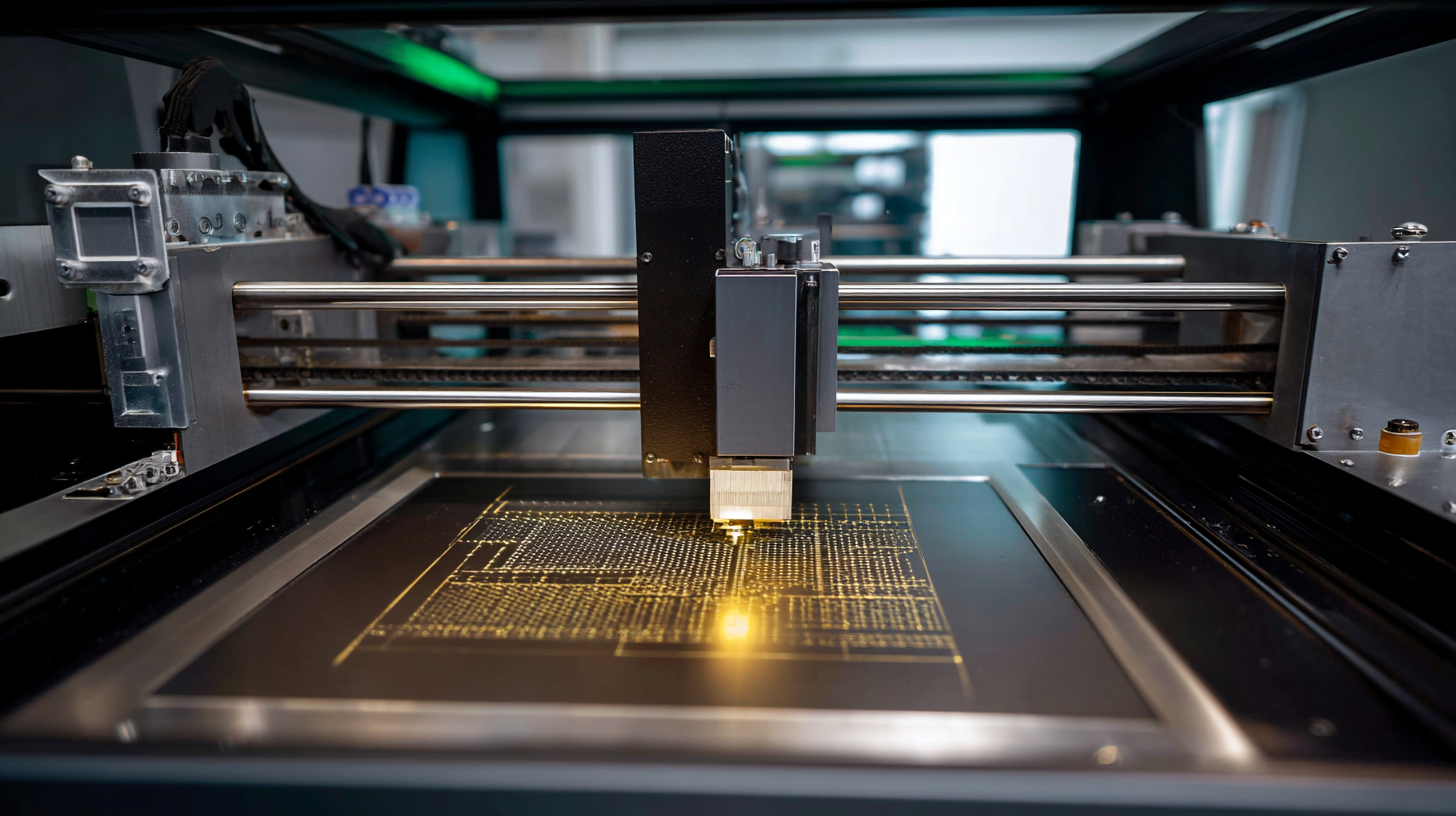

As industries continue to evolve in the face of increasing demands for personalization and efficiency, the emergence of the metal printing machine stands at the forefront of this revolution. According to a report by MarketsandMarkets, the metal 3D printing market is expected to reach $2.6 billion by 2025, growing at a CAGR of 25.4%. This growth trajectory underscores the significance of metal printing machines in facilitating unprecedented levels of customization across various sectors, including aerospace, automotive, and healthcare. By enabling the production of intricate designs and complex geometries, these machines not only reduce material waste but also shorten lead times, allowing companies to respond more swiftly to market trends. The transformational potential of metal printing technology is reshaping manufacturing paradigms, making it a crucial tool for businesses striving to stay competitive in a rapidly changing landscape.

The rise of metal printing technology is revolutionizing customization capabilities across various industries. Traditional manufacturing methods often impose limitations on design intricacies and material utilization. However, metal printing machines enable unparalleled precision and flexibility, allowing businesses to create complex geometries that were previously unattainable. This advancement opens doors for innovations in fields such as aerospace, automotive, and healthcare, where tailored components can significantly enhance performance and efficiency.

Moreover, the ability to produce customized metal parts on-demand drastically reduces lead times and inventory costs. Companies can now respond to market demands rapidly, designing and printing unique components that meet specific client needs. This shift not only streamlines production processes but also fosters a culture of innovation, empowering engineers and designers to experiment freely. As industries continue to embrace metal printing technology, the future of customization looks promising, paving the way for more sustainable and efficient manufacturing solutions.

Metal printing technologies are reshaping various industries by offering unprecedented levels of customization and efficiency. For instance, the aerospace sector has greatly benefited from metal 3D printing, allowing for the production of lightweight components that improve fuel efficiency and performance. Manufacturers can create complex geometries that traditional methods cannot achieve, thus reducing the weight of aircraft parts without compromising strength.

In the automotive industry, metal printing facilitates rapid prototyping, enabling manufacturers to quickly iterate designs and components tailored to specific vehicle models. This not only speeds up the production process but also allows for on-demand production of spare parts, reducing inventory costs.

**Tip:** When integrating metal printing technologies into your production line, start with small pilot projects to evaluate the technology's capabilities and limitations. This approach will help refine your processes and identify areas for improvement before scaling up.

Another area transformed by metal printing is medical device manufacturing. Customized implants and surgical tools can be created to meet the precise needs of individual patients. This personalized approach enhances patient outcomes and streamlines surgical procedures.

**Tip:** Collaborate with healthcare professionals early in the design process to ensure that the customizations align with clinical needs and regulatory standards, thereby facilitating a smoother path to market.

Customization in metal printing offers several compelling advantages for businesses looking to innovate and stay competitive. According to a report from Smithers Pira, the global market for additive manufacturing is projected to reach $35 billion by 2025, signifying a robust growth trend that underscores the importance of tailored solutions. Metal printing allows companies to create complex geometries and lightweight components that are not only efficient but also cost-effective. By reducing material waste and decreasing the development time for prototypes, businesses can respond swiftly to market demands.

One of the key benefits of customization is the ability to meet specific client needs. This flexibility empowers manufacturers to produce parts that are specifically optimized for their applications, enhancing product performance. For instance, industries such as aerospace and automotive are leveraging custom metal parts to improve fuel efficiency and reduce emissions. A report by Wohlers Associates highlighted that 54% of companies employed additive manufacturing to create customized parts, resulting in significant performance gains.

Tip: When considering metal printing for customization, invest in a robust design software that can handle complex geometries. This will not only streamline the design process but also ensure that the final product meets both functional and aesthetic requirements.

Tip: Collaborate with your material suppliers to explore innovative alloys tailored to your production needs. Custom materials can significantly enhance the performance of your printed parts, driving better results and satisfaction.

The future of metal printing is set to revolutionize customization techniques across various industries, driven by advancements in additive manufacturing. According to a report by ResearchAndMarkets, the global metal 3D printing market is projected to reach $1.4 billion by 2027, reflecting a compound annual growth rate (CAGR) of 26%. This growth underscores the increasing demand for tailored solutions in sectors such as aerospace, automotive, and healthcare, where precision and performance are crucial.

In addition to speed and efficiency, metal printing technology significantly enhances the customization process by enabling complex geometries that were previously impossible with traditional manufacturing methods. A study from Wohlers Associates highlights that 68.5% of companies using additive manufacturing for metal parts report improved product performance. As businesses continue to embrace digital manufacturing, the integration of artificial intelligence and machine learning into metal printing machines will further streamline customization workflows, enabling real-time adjustments and optimizations. This shift emphasizes the necessity for industries to adapt and innovate, ensuring they remain competitive in an increasingly personalized marketplace.

The implementation of metal printing innovations presents several challenges that industries must navigate to fully harness their potential. One of the primary obstacles is the technological complexity involved in operating advanced metal printing machines. These systems require not only specialized knowledge for operation but also ongoing training for staff to ensure proficiency in handling intricate designs and materials. This steep learning curve can lead to delays in production and increased operational costs, thereby making it essential for companies to invest in comprehensive training programs and user-friendly software interfaces.

Another significant challenge is ensuring the quality and consistency of printed metal parts. Achieving precise tolerances and desired mechanical properties often necessitates rigorous quality control processes. Variations in raw material properties, machine calibration, and environmental conditions can result in defects that affect the final product. To address these issues, industries are turning to data analytics and machine learning technologies to monitor production in real-time. By leveraging these innovative approaches, companies can optimize their printing processes, drastically reduce error rates, and improve overall production efficiency, paving the way for a more reliable implementation of metal printing solutions.

© Copyrights Levil Technology Corp 2022