The Future of Rapid Mold Change Technology Driving Efficiency and Innovation in Manufacturing

In today's fast-paced manufacturing landscape, the demand for efficiency and innovation is more pressing than ever. One of the most transformative advancements in this arena is the Quick Mold Change System, which significantly reduces downtime and boosts productivity. As manufacturers strive to keep up with market fluctuations and customer demands, the ability to swiftly change molds can give companies a critical edge. This technology not only streamlines production processes but also enhances flexibility, enabling manufacturers to adapt quickly to new product designs and variations. As we delve deeper into the future of rapid mold change technology, it becomes clear that embracing digital advancements will further revolutionize manufacturing practices, fostering a new era of efficiency and creativity across industries.

The Evolution of Rapid Mold Change Technology: Past, Present, and Future

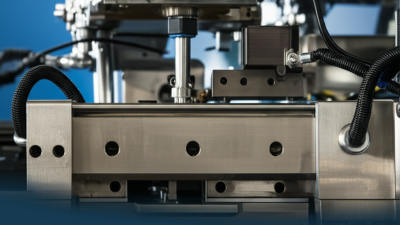

The evolution of rapid mold change technology has transformed the manufacturing landscape, paving the way for greater efficiency and innovation. In the past, mold changes were time-consuming processes that could lead to costly production delays. However, advancements in automation and precision engineering have drastically reduced the time required for these changes, enabling manufacturers to respond more swiftly to market demands.

As we look to the present, companies are increasingly adopting modular mold systems that enhance flexibility. These systems allow for quick adjustments and seamless integration into existing production lines. This shift not only decreases downtime but also enables manufacturers to experiment with different designs without extensive retooling.

**Tip:** Consider investing in smart technologies that monitor mold performance in real-time, which can help identify potential issues before they escalate, ensuring smoother operations and minimal downtime.

Looking forward, the future of rapid mold change technology promises even more exciting developments. Emerging practices such as 3D printing in mold creation and the use of AI for optimizing mold designs are on the horizon. The ability to swiftly adapt to trends will be critical for manufacturers aiming to remain competitive in a fast-evolving market.

**Tip:** Keep an eye on industry trends and invest in training for your team to ensure they are equipped to handle new technologies, maximizing the potential benefits of rapid mold change systems.

The Future of Rapid Mold Change Technology Driving Efficiency and Innovation in Manufacturing - The Evolution of Rapid Mold Change Technology: Past, Present, and Future

| Year | Technology Development | Efficiency Gains (%) | Key Innovations | Industry Impact |

|---|---|---|---|---|

| 1990 | Introduction of Modular Molds | 15% | Modularity concept | Automotive, Consumer Goods |

| 2005 | Rapid Change Systems | 25% | Quick-connect systems | Electronics, Packaging |

| 2015 | Smart Mold Technologies | 35% | Data integration and sensors | Medical, Aerospace |

| 2022 | Fully Automated Change Systems | 50% | Robotics and AI | Consumer Electronics, High Volume Production |

| 2025 (Projected) | Integrated IoT Mold Systems | 60% | Predictive maintenance | Industry 4.0, Smart Factories |

Key Benefits of Rapid Mold Change in Modern Manufacturing Processes

The rapid mold change technology is revolutionizing modern manufacturing processes by significantly enhancing efficiency and innovation. One of the key benefits of this technology is the drastic reduction in downtime during production. Traditional mold change procedures can be time-consuming and labor-intensive, often leading to extended periods of inactivity that hamper productivity. However, with rapid mold change systems, manufacturers can switch out molds in a fraction of the time, allowing for seamless transitions between different production runs. This agility not only boosts productivity but also enables manufacturers to respond quickly to market demands and shifts in consumer preferences.

Another advantage of rapid mold change is the improvement in product quality. Faster mold changes lead to more precise adjustments in production settings, minimizing the margin for error. Additionally, the ability to quickly implement new molds facilitates experimentation and innovation in product design, allowing manufacturers to test new concepts without the fear of long lead times or high costs associated with conventional mold setups. As companies embrace this technology, they are not only improving their operational efficiency but also fostering an environment of creativity and responsiveness, essential for staying competitive in today’s fast-paced manufacturing landscape.

Market Trends Shaping the Future of Rapid Mold Change by 2025

The rapid mold change technology is transforming the manufacturing landscape, driven by market trends that emphasize efficiency, productivity, and innovation. According to a recent report by MarketsandMarkets, the global rapid mold change market is expected to grow from USD 1.1 billion in 2020 to USD 1.7 billion by 2025, at a CAGR of 9.1%. This growth is largely fueled by the increasing need for shorter production cycles and the demand for high-quality output in industries such as automotive, electronics, and consumer goods.

As manufacturers face pressure to reduce downtime, rapid mold change systems provide a viable solution by significantly speeding up the mold swapping process and minimizing machinery idleness. A study conducted by Deloitte indicates that companies employing advanced mold change technologies can achieve a 20-30% increase in overall equipment efficiency (OEE). Furthermore, the integration of smart technologies and automation within rapid mold change processes is set to further enhance productivity and resource management. The convergence of these trends by 2025 will be pivotal for manufacturers striving to maintain competitiveness in an increasingly dynamic market.

Innovative Technologies Driving Efficiency in Mold Change Operations

In the ever-evolving landscape of manufacturing, the quest for efficiency has led to significant advancements in rapid mold change technology. The need for quicker turnaround times and reduced downtime has prompted manufacturers to adopt innovative solutions that streamline mold change operations. From automated systems to advanced material handling techniques, these technologies not only enhance productivity but also contribute to high-quality output.

One notable innovation in this domain is the integration of smart technologies that utilize IoT and AI. These systems provide real-time data analytics, allowing manufacturers to monitor the mold changing process efficiently. By identifying bottlenecks and predicting maintenance needs, manufacturers can significantly cut down on wasted time and resources. Furthermore, the introduction of modular mold designs enables manufacturers to switch out molds swiftly with minimal manual intervention, thereby decreasing labor costs and enhancing flexibility in production lines.

As we look towards the future, embracing these cutting-edge technologies will be crucial for manufacturers eager to stay competitive. The focus on rapid mold change efficiency not only supports the demand for customization but also fosters a culture of innovation, ultimately reshaping the manufacturing landscape for better efficiency and sustainable practices.

Case Studies: Success Stories of Rapid Mold Change Implementation in Industries

In recent years, rapid mold change technology has transformed the manufacturing landscape, significantly improving efficiency and innovation. Case studies from various industries highlight the successful implementation of this technology, revealing its impact on productivity and operational flexibility. For instance, a leading automotive parts manufacturer adopted rapid mold change systems that reduced mold swapping time from hours to mere minutes. This not only increased the production rate but also allowed for a more agile response to market demands and customization requests.

Another compelling example comes from the consumer goods sector, where a well-known packaging company integrated rapid mold changes to enhance its product line versatility. By enabling faster transitions between different packaging molds, the company was able to introduce new products more quickly and efficiently, leading to a notable increase in market share. These success stories illustrate that companies willing to invest in rapid mold change technology are not only reaping immediate benefits but also positioning themselves for sustainable growth and innovation in the competitive manufacturing environment.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी