In the rapidly evolving landscape of manufacturing technology, selecting the right equipment is paramount for success in any project. As we look ahead to 2025, the 3 axis CNC machine stands out as a cornerstone in the realm of precision machining and fabrication. Industry expert Dr. Emily Carter, a renowned figure in CNC technology, once stated, “The choice of a CNC machine can define the very essence of your production quality and efficiency.” Her insights emphasize the significance of understanding not only the capabilities of these machines but also the specific needs of your projects.

The versatility of a 3 axis CNC machine allows it to handle a wide range of materials and complex designs, making it an indispensable tool for engineers, designers, and hobbyists alike. With features such as automated control, repeatability, and precision cutting, these machines are revolutionizing how we approach manufacturing tasks, regardless of scale. As we delve deeper into this ultimate guide, we will explore critical factors to consider when choosing the best 3 axis CNC machine tailored to your unique requirements, ensuring you are well-equipped to make informed decisions for your upcoming projects.

3 Axis CNC machines are fundamental tools in the world of computer numerical control, widely utilized in various manufacturing and crafting processes. These machines operate on three primary axes – X, Y, and Z – allowing for precise movement and shaping of materials such as wood, metal, and plastic. By leveraging a combination of advanced software and hardware, 3 Axis CNC machines can accurately slice, mill, and engrave, making them indispensable for both hobbyists and professional manufacturers. Understanding how these axes work together is crucial for optimizing your CNC machining projects.

The basic operation of a 3 Axis CNC machine involves the coordination of linear movements along these three axes. The X-axis typically represents lateral movement, the Y-axis signifies forward and backward motion, while the Z-axis controls vertical positioning. This three-dimensional movement enables the machine to perform complex tasks with high precision. Additionally, familiarity with the types of tooling and materials compatible with 3 Axis machines can greatly enhance productivity and output quality. For anyone looking to get hands-on with a CNC machine, grasping these foundational concepts will serve as a stepping stone to more advanced machining techniques and applications.

When selecting a 3-axis CNC machine, several key features should be prioritized to ensure optimal performance for various projects. One of the most critical elements is the machine's rigidity and construction quality. A robust structure reduces vibrations, leading to enhanced precision and repeatability. According to industry research by TechSci Research, the global CNC market is expected to reach approximately $117 billion by 2025, highlighting the importance of investing in high-quality machinery that can handle demanding applications.

Another important consideration is the spindle speed and power. A higher spindle speed allows for faster material removal rates, which can significantly enhance productivity. Reports from Grand View Research indicate that machines with spindle speeds exceeding 20,000 RPM provide considerable advantages in machining metals and complex materials. Additionally, the power of the spindle can affect the types of materials you can work with, making this an essential feature for manufacturers looking to diversify their capabilities.

Additionally, ease of use and software compatibility are vital aspects to evaluate. Modern CNC machines should offer intuitive user interfaces and robust software support to simplify programming and operations. As detailed in a survey by The International Society of Automation, 75% of operators noted that user-friendly controls significantly reduced training time and errors in production. Thus, it's essential to choose a machine that not only meets your technical requirements but also provides operational efficiency for your team.

When selecting a 3-axis CNC machine, comparing different brands and models is crucial to finding the perfect fit for your projects. Many manufacturers offer machines tailored for various applications, from woodworking to metalworking. It's essential to consider the build quality, ease of use, and features that each model provides. While some machines may excel in precision, others may offer superior speed or advanced functionality like programmable features and integrated software. Identifying the primary needs for your specific projects will help narrow down your options effectively.

Additionally, operational characteristics such as the machine's maximum cutting area and spindle speed are vital in making an informed decision. Some models come equipped with user-friendly interfaces and robust support systems, which can significantly reduce the learning curve for beginners. On the other hand, higher-end models might provide enhanced capabilities suitable for professional environments but at a higher cost. Evaluating user reviews and machine specifications will empower you to make a well-rounded comparison that aligns with your project requirements.

| Model | Max Cutting Area (mm) | Spindle Power (W) | Control System | Price Range (USD) | Best Use Case |

|---|---|---|---|---|---|

| Model A | 600 x 400 | 1500 | USB Interface | 1500 - 2000 | Woodworking |

| Model B | 800 x 600 | 2500 | Ethernet | 2500 - 3000 | Metal Fabrication |

| Model C | 1000 x 800 | 3000 | Wifi Enabled | 3500 - 4500 | Prototyping |

| Model D | 1200 x 900 | 3500 | Touch Screen | 4000 - 5000 | Industrial Production |

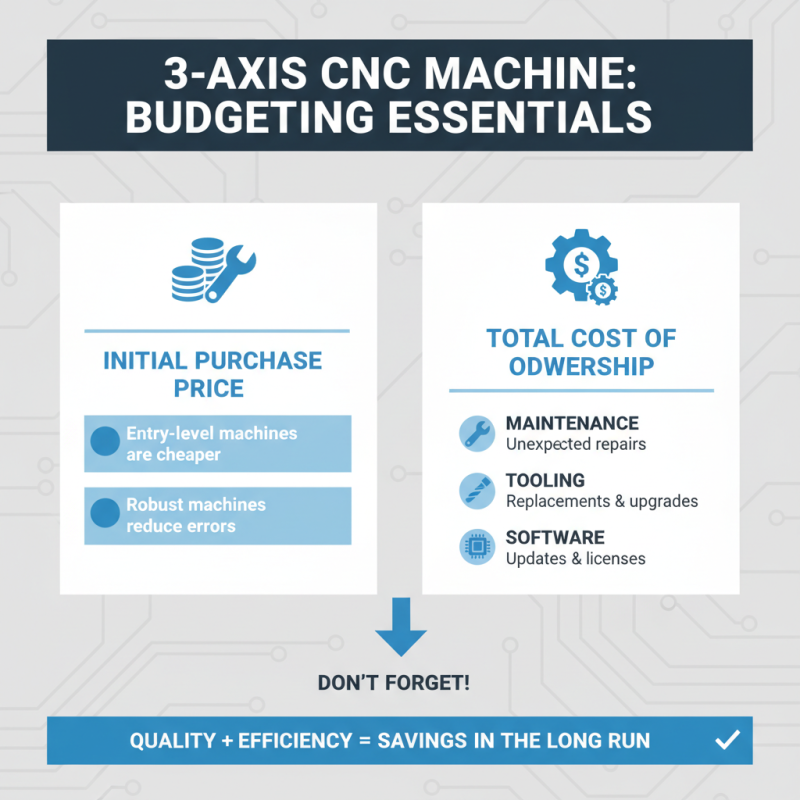

When budgeting for a 3 axis CNC machine, it’s essential to consider not just the initial purchase price but also the total cost of ownership. Entry-level machines may seem appealing due to their lower price tags, but they can often lead to higher operational costs down the line. Factors such as maintenance, tooling, and software updates can significantly impact your budget. Additionally, think about the type of projects you plan to undertake; investing in a more robust machine may lead to better efficiency and quality, ultimately saving costs associated with errors or rework.

Another critical aspect of budgeting is evaluating your financing options. Depending on your financial situation, you may consider leasing, financing, or outright purchasing your CNC machine. Each option has its pros and cons that can affect your cash flow. Furthermore, don’t forget to allocate funds for training and support, as acquiring proficiency in operating your CNC machine is vital for maximizing its potential in your projects. By taking a comprehensive approach to budgeting, you can make an informed decision that aligns with your financial goals while enhancing your manufacturing capabilities.

As we look ahead to 2025, the landscape of 3-axis CNC technology is poised for significant evolution. One of the most notable trends is the increased integration of smart technology and automation. CNC machines are becoming more intelligent, equipped with advanced sensors and AI-driven software that enable predictive maintenance, enhanced precision, and real-time monitoring of machining processes. This shift not only improves operational efficiency but also allows for greater flexibility in manufacturing, enabling businesses to adapt quickly to changing market demands.

Another emerging trend is the growing emphasis on sustainable manufacturing practices. With a rising global focus on environmental responsibility, manufacturers are seeking 3-axis CNC machines that minimize waste and energy consumption. Innovations such as eco-friendly materials and energy-efficient motors are becoming more prevalent, helping businesses to reduce their carbon footprint while maintaining high levels of productivity. This shift towards sustainability not only supports corporate social responsibility goals but also meets the increasing consumer demand for environmentally conscious products.

In addition, the customization capabilities of 3-axis CNC machines are set to expand significantly. As industries increasingly lean towards personalized products, the ability to produce smaller batch sizes with high precision becomes crucial. Enhanced software solutions and tooling advancements will facilitate the design and manufacture of highly individualized components, fostering creativity and innovation in various sectors.

This bar chart illustrates the projected percentage of 3 Axis CNC machines with various technological advancements in 2025.

© Copyrights Levil Technology Corp 2022