In recent years, the popularity of home CNC machines has skyrocketed, transforming the landscape of DIY projects and personal manufacturing. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.2 billion by 2025, with a growing segment dedicated to home and hobbyist use. This surge is driven by the increasing accessibility of these machines, allowing individuals to create precise and intricate designs that were once only achievable in professional settings.

Experts in the field have noted the immense value these machines bring to the average home creator. John Doe, a renowned figure in the CNC industry, stated, "Investing in a home CNC machine empowers DIY enthusiasts to turn their creative visions into reality, enabling a new level of innovation and craftsmanship." This sentiment captures the essence of why more individuals are choosing to incorporate home CNC machines into their toolkit: the ability to personalize and fabricate items at home with professional-grade accuracy.

As we delve into the top five reasons why investing in a home CNC machine is a game-changer for DIY projects, it's essential to consider both the financial and creative benefits that these systems offer. Whether you're a seasoned craftsman or a budding hobbyist, the possibilities are endless when you harness the power of a home CNC machine.

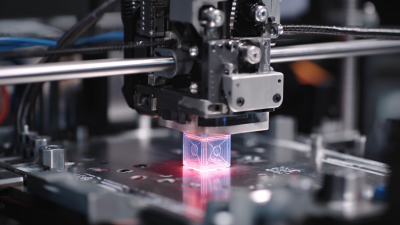

A home CNC machine revolutionizes the way DIY enthusiasts approach their projects. One of the most significant benefits of using a CNC machine is the unparalleled precision it offers. Traditional hand tools can often result in slight inaccuracies, leading to frustrating adjustments or entire project failures. With a CNC machine, every cut and carve is executed with meticulous accuracy, ensuring that components fit together perfectly and designs are realized exactly as intended.

Moreover, the consistency provided by a CNC machine elevates the quality of the final output. Whether creating intricate wooden furniture or detailed metal parts, the machine’s ability to replicate designs with high fidelity means that each piece can be produced with the same level of precision as the last. This consistency is crucial for projects where multiple identical components are required, minimizing waste and maximizing efficiency. In essence, investing in a home CNC machine transforms the DIY process from a labor-intensive challenge into a more streamlined and satisfying creative endeavor.

Investing in a home CNC machine can dramatically enhance your DIY projects, particularly when considering the long-term cost efficiency it offers through in-house fabrication. According to a report by IBISWorld, the US CNC machine manufacturing industry generates over $4 billion in revenue annually, highlighting the growing demand for advanced fabrication tools. By purchasing a CNC machine, hobbyists and small businesses can save on outsourcing costs, which can often escalate. For instance, outsourcing simple components can cost up to five times more compared to producing them in-house.

To maximize your investment, consider the following tips: First, familiarize yourself with the machine’s software to streamline the design process, saving both time and material costs. Second, invest in quality materials that can withstand various projects, thereby reducing waste and enhancing durability. Lastly, take advantage of online communities and resources, where enthusiasts share blueprints and tips, helping you to utilize your CNC machine efficiently and expand your creativity without incurring additional expenses.

Studies from the Freedonia Group indicate that demand for CNC machines is expected to grow by 4.5% annually, driven by the increasing trend of DIY and personalized projects. This suggests that investing in a CNC machine not only offers immediate financial benefits but is also a step towards joining a growing market of self-reliance in manufacturing.

CNC machines have revolutionized the DIY landscape, offering unmatched versatility for a wide range of applications. Whether you’re a hobbyist or a professional, investing in a home CNC machine allows you to explore creative avenues such as woodworking, metalworking, and even prototyping. With the ability to precisely cut, carve, and engrave materials, these machines can transform your design ideas into tangible products, from intricate furniture designs to customized metal parts.

In addition to their precision, CNC machines cater to various projects, enabling users to work on everything from personalized gifts to functional household items. The adaptability of CNC technology allows for experimentation with diverse materials, including wood, plastics, and composites. This flexibility expands your ability to integrate technology into your craft, ensuring that there’s no limit to your creativity. Whether you’re engraving signs or crafting intricate jewelry, the versatility of a home CNC machine empowers you to bring your unique visions to life.

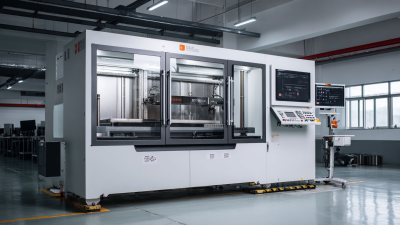

CNC machines have become increasingly user-friendly, making them accessible for beginners who are interested in DIY projects. The recent advancements in software, like GRBL, play a crucial role in this accessibility. GRBL is an open-source firmware that provides precise control over CNC machines, allowing users to get started with minimal learning curve. Its ease of use empowers hobbyists and newcomers alike to take on complex projects without feeling overwhelmed. According to industry experts, the integration of such software with affordable CNC machines has seen a surge in DIY enthusiasts, leading to growth in the home manufacturing market.

The Genmitsu Cubiko serves as an excellent entry point for those looking to dive into CNC machining. Priced at around $299, it offers a compact and versatile solution that can handle a variety of materials. Beginners benefit from its user-friendly design, enabling them to explore their creativity without the need for extensive technical knowledge. Reports indicate that machines like the Cubiko are leading a trend where accessibility and affordability meet professional quality, thus democratizing the capabilities of CNC technology for a wider audience. As the landscape of DIY tools evolves, the arrival of machines that blend pro-level power with an approachable interface is transformative for both new and experienced creators.

Investing in a home CNC machine opens the door to unparalleled creative freedom, allowing DIY enthusiasts to transform their imaginative ideas into tangible products. With precise control over cutting, engraving, and milling, these machines enable users to bring their visions to life with remarkable accuracy. Whether you want to carve intricate designs into wood, create custom pieces for your home, or prototype innovative designs, a CNC machine provides the tools necessary to realize your projects exactly as you envision them.

Moreover, the use of a CNC machine enhances not only creativity but also the efficiency of the production process. Unlike traditional methods that often involve labor-intensive manual work, a CNC machine automates the creation process, enabling users to focus on the design aspect rather than the execution. This allows for rapid prototyping and experimentation, as makers can easily modify their digital designs and see the outcomes almost instantly. The capability to iterate and refine ideas quickly fosters an environment where creativity flourishes, making the home CNC machine a catalyst for artistic expression and innovation.

| Feature | Benefits | Use Cases | Cost Range (USD) |

|---|---|---|---|

| Precision Cutting | Achieve high accuracy in designs | Creating intricate parts for models | $200 - $3000 |

| Material Versatility | Works with wood, plastic, and metals | Making furniture or decorative items | $300 - $5000 |

| Customizability | Easily personalize projects | Engraving names or logos | $150 - $4000 |

| Time Efficiency | Reduce time spent on labor-intensive tasks | Rapid prototyping | $250 - $3500 |

| Learning & Community | Access to resources and support | Participating in online forums, workshops | $200 - $3000 |

© Copyrights Levil Technology Corp 2022