In the realm of precision engineering, mastering "5 axis machining" is crucial for achieving high efficiency and accuracy. Renowned expert Dr. Elizabeth Chang, a leader in advanced manufacturing techniques, emphasizes, "5 axis machining allows us to create complex geometries that were once unthinkable." Her insight underscores the transformative impact of this technology.

As industries evolve, the demand for intricate designs grows. Many engineers still struggle with the learning curve associated with 5 axis machining. Gaining proficiency requires time and practice. Mistakes often occur in programming and tool selection. This journey is filled with challenges, but these obstacles can be stepping stones to innovation.

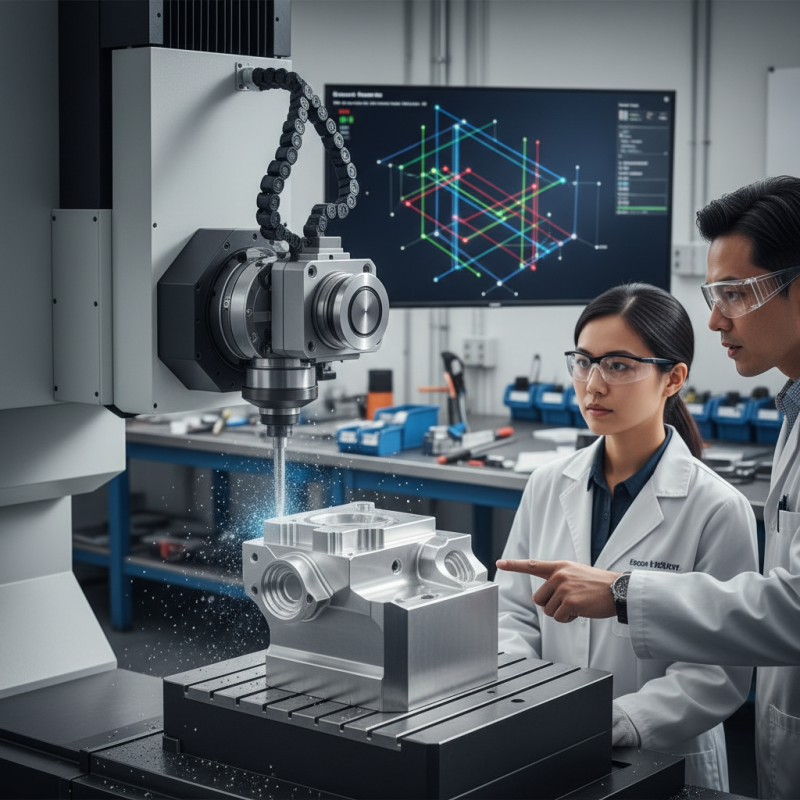

Exploring 5 axis machining techniques involves understanding tool paths and machine setups. Precision matters at every stage. Each component must align perfectly to avoid errors. An ideal setup can significantly enhance productivity and quality. Yet, even seasoned professionals occasionally find themselves reevaluating their approaches. Reflecting on past experiences can lead to breakthroughs, driving future successes in the world of machining.

5 axis machining is an advanced technique that greatly enhances precision in manufacturing. Understanding its basics is essential for optimizing production workflows. Unlike traditional machining, this method allows tools to move along five different axes. This movement significantly increases the complexity of parts that can be created. It also reduces the need for multiple setups, saving time and minimizing errors.

The technology involves both mechanical and digital components. Operators must understand the machine's capabilities and limitations. The software plays a crucial role in programming complex cuts. A mistake in programming can lead to wasted materials and time. Learning to navigate this technology takes practice and patience. Every operator faces challenges, particularly when refining techniques.

Quality control is another vital aspect of 5 axis machining. Regular inspections help catch potential issues early. However, even the best systems can produce errors. Emphasizing continuous learning and improvement is essential. Each project presents new opportunities for growth. Operators should document their experiences to enhance their skills over time.

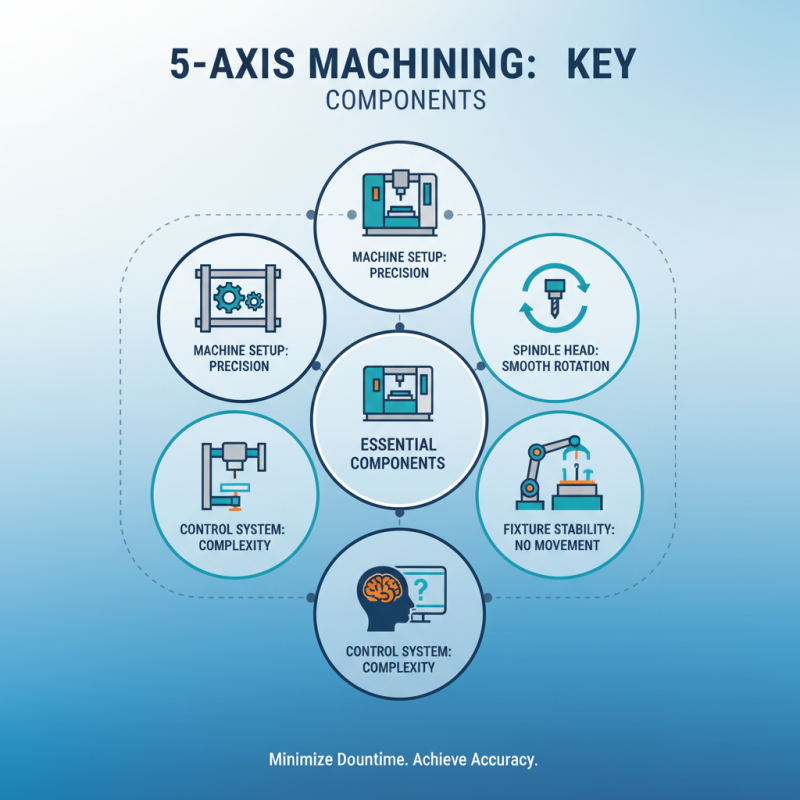

When diving into 5-axis machining, understanding the key components is essential. The machine setup is critical for achieving precision. Spindle heads should allow for smooth rotation. Tool changers need to work seamlessly, minimizing downtime. Fixture stability is vital, as any movement can lead to errors. The control system must be user-friendly, but complex processes may still confuse operators.

Operators often struggle with setup. Aligning the workpiece correctly can be challenging. A misalignment of even a fraction can affect the end result. Lubrication systems must be checked frequently. Neglecting this can lead to overheating and machining errors. Operator training is just as important. A skilled operator can make significant differences, but everyone learns at their own pace. Practice is crucial, and mistakes are part of the journey.

Mastering 5 Axis machining techniques can significantly enhance precision. This advanced method allows for complex geometries that traditional machining cannot achieve. By utilizing multiple axes, operators can reduce setups and improve accuracy. However, this complexity may lead to challenges. Understanding the machine's capabilities is essential.

One important factor is tool selection. Choosing the right tool can improve both speed and precision. High-quality tools may be pricier, but the investment often pays off in reduced errors. Regular maintenance of machinery is equally crucial. Neglecting this can lead to unexpected breakdowns and costly reworks. Operators should also reflect on their programming skills. Complex part programs can introduce human error.

Implementing simulation software is a practical strategy. It allows for testing and refining machining processes without wasting materials. However, reliance on simulation can lead to overconfidence. Mistakes can still happen on the shop floor. Regular training and knowledge updates are vital. Encouraging a culture of feedback can further enhance precision in operations.

This bar chart illustrates the precision rating of various 5 axis machining techniques. The scores reflect the effectiveness of each technique in achieving high precision in machining processes, which is crucial for manufacturing high-quality components.

In the realm of five-axis machining, optimizing efficiency requires innovative toolpath strategies. By focusing on precise movements, manufacturers can significantly reduce production time. Advanced toolpath algorithms, like adaptive strategies, allow for real-time adjustments. This flexibility leads to smoother transitions and better surface finishes.

However, it's essential to acknowledge that not every approach yields perfect results. Sometimes, tool wear can occur faster than anticipated. In some cases, unexpected vibrations may affect the machining quality. Continuous monitoring and adjustments are crucial to mitigate these issues. Experimentation is necessary to fine-tune each setup, identifying what works best for specific projects.

Implementing dynamic toolpath strategies creates new opportunities but also poses challenges. Engineers must constantly evaluate their methods. A balance between cutting speed and precision is vital. Through this process, developers learn to adapt and refine their techniques, ultimately enhancing both productivity and quality.

| Technique | Description | Advantages | Applications | Efficiency Improvement (%) |

|---|---|---|---|---|

| Dynamic Toolpath | Utilizes real-time feedback for adaptive cutting. | Reduces cycle times. | Aerospace components. | 20 |

| 3D Toolpath Generation | Creates complex geometries in a single pass. | Increases precision. | Medical devices. | 30 |

| Collision Detection | Prevents tool and workpiece collisions through simulation. | Enhances tool life. | All manufacturing sectors. | 15 |

| High-Speed Machining | Merges fast tool movement with optimal feed rates. | Lowers production costs. | Automotive parts. | 25 |

| Multi-Axis Simultaneous Control | Enables simultaneous control of multiple axes. | Produces intricate shapes. | Aerospace and defense. | 40 |

5-axis machining offers precision and efficiency, but it also presents common challenges. One issue is tool accessibility. Machining complex geometries often means that the tools can’t reach certain areas. This limitation can lead to unfinished surfaces or increased cycle times. Identifying these problematic zones early helps in planning the setup more effectively.

Another challenge involves the programming complexity. The intricacies of 5-axis tools require advanced skills. Mistakes in the code can lead to costly errors. Often, operators may underestimate the importance of simulation before actual machining. Investing time in creating accurate simulations can save significant resources in the long run. Additionally, vibration can be a significant problem during machining. It affects surface finishes and can lead to premature tool wear. Monitoring and minimizing vibrations should be a top priority during setup.

© Copyrights Levil Technology Corp 2022