Mastering Quick Mold Change Systems with Practical Step by Step Techniques

In the rapidly evolving manufacturing landscape, the adoption of Quick Mold Change Systems (QMCS) has emerged as a pivotal factor in enhancing productivity and minimizing downtime. According to a report by MarketsandMarkets, the global market for mold change systems is expected to reach $1.2 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth underscores the importance of efficient systems that allow manufacturers to respond quickly to changing demands and streamline their production processes. As companies, especially those based in China, focus on quality while competing on a global scale, mastering practical techniques for implementing QMCS becomes essential. Not only does this approach lead to significant cost savings, but it also positions manufacturers to leverage scalability and innovation, ultimately contributing to a more competitive edge in both domestic and international markets.

Understanding the Importance of Quick Mold Change Systems in Modern Manufacturing

In today’s fast-paced manufacturing environment, the importance of quick mold change systems cannot be overstated. These systems significantly enhance productivity by reducing downtime during mold swaps, allowing manufacturers to respond swiftly to changing market demands. As industries strive for greater efficiency, the ability to minimize idle time becomes a competitive advantage. Implementing a quick mold change system can streamline operations, ensuring that production lines remain active and efficient.

Moreover, quick mold change systems promote flexibility in production. With the capability to easily switch between different molds, manufacturers can diversify their product offerings without the usual long wait times associated with traditional mold changes. This adaptability not only caters to consumer preferences but also enables manufacturers to pivot quickly in response to market trends. As a result, investing in these systems is not merely a matter of convenience—it's a strategic move that can transform manufacturing processes, making them more agile and resilient in an ever-evolving landscape.

Importance of Quick Mold Change Systems in Modern Manufacturing

Key Components of Effective Quick Mold Change Systems: A Comprehensive Overview

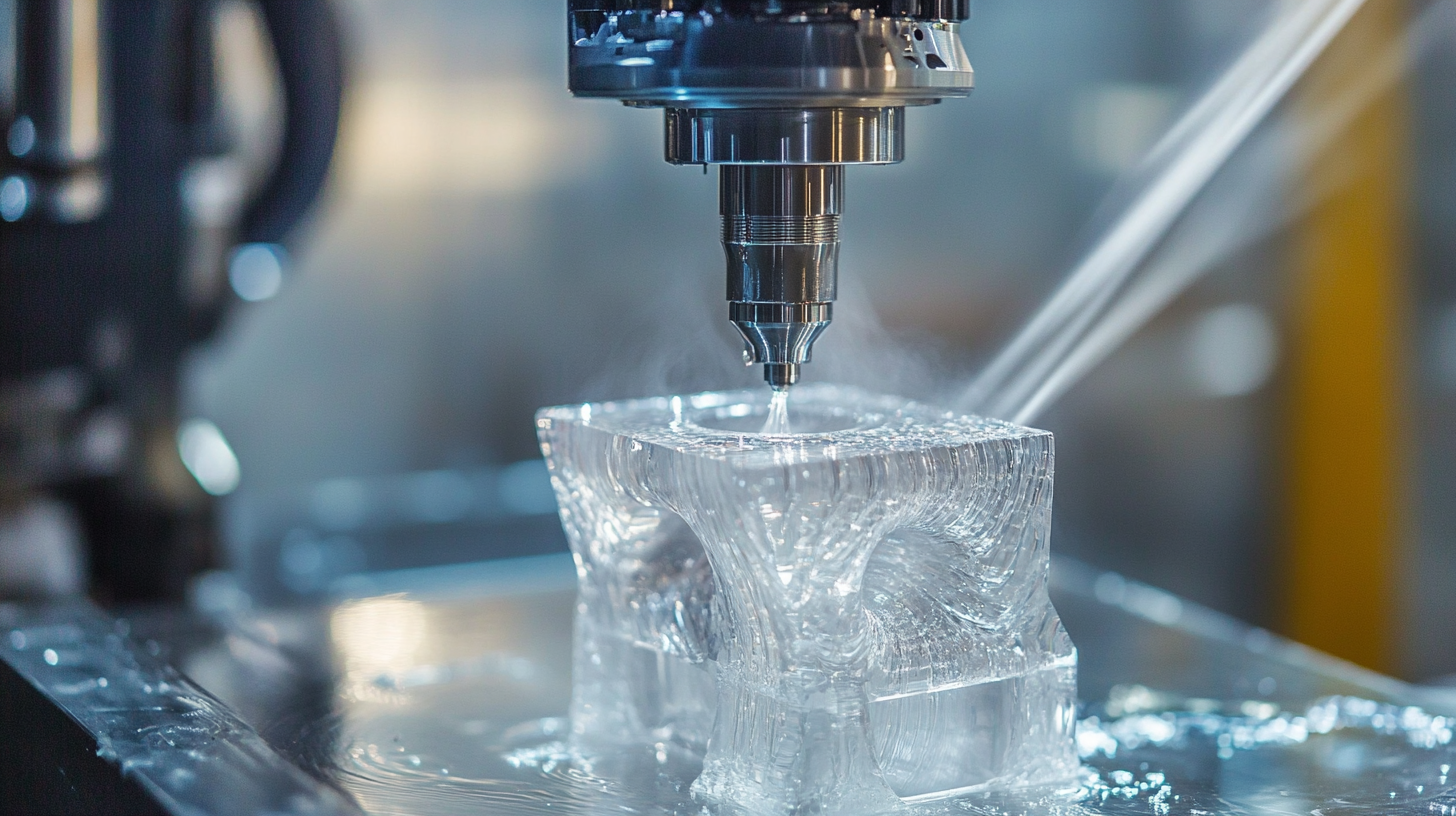

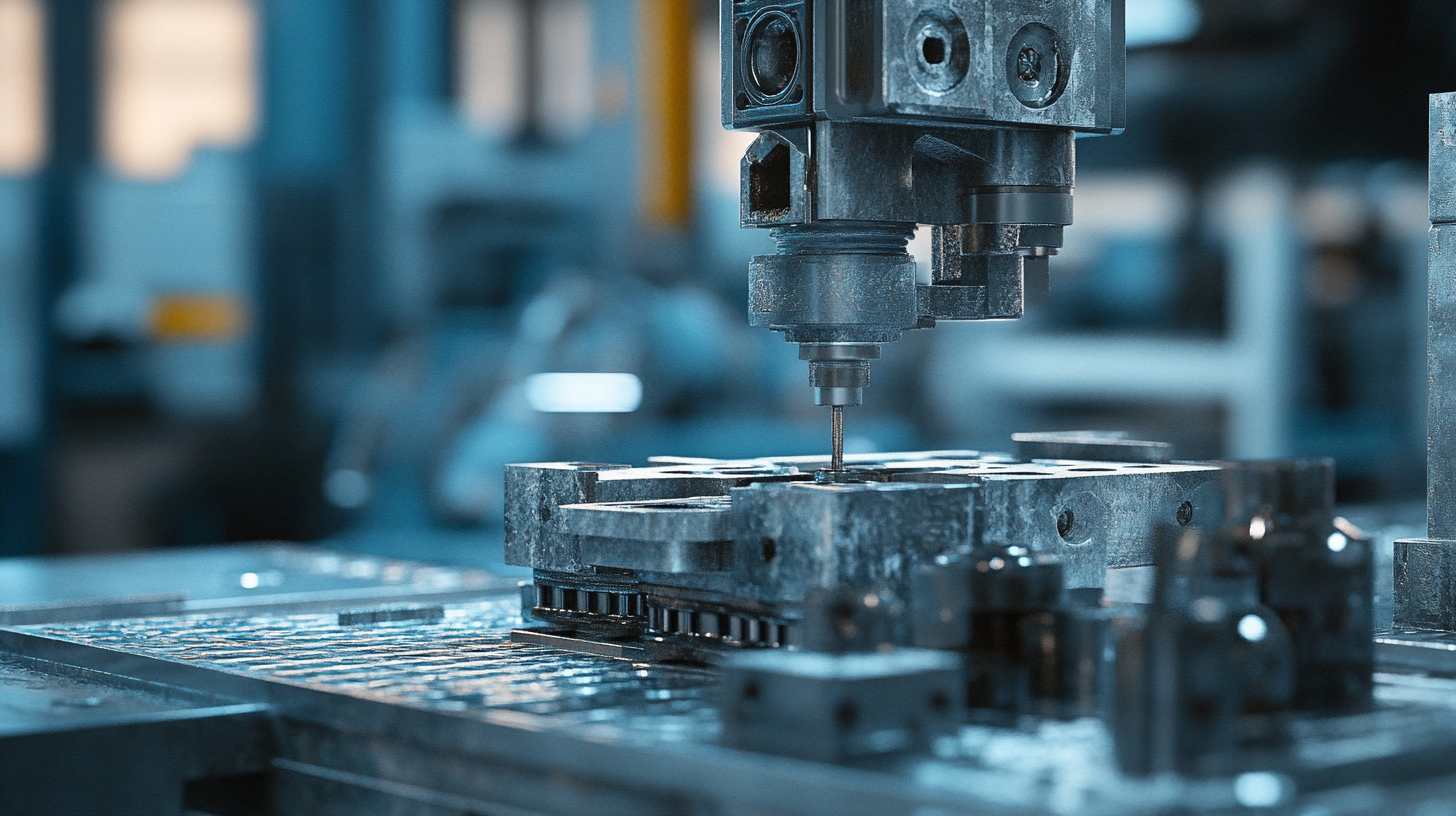

Effective quick mold change systems are essential for optimizing production efficiency and minimizing downtime. At the core of these systems are several key components that facilitate a seamless transition between different molds. Start with the mold handling equipment, which includes cranes and automated guided vehicles, designed to safely transport molds from storage to the injection machine. This equipment plays a vital role in reducing manual labor and the risk of damage during the mold change process.

Another critical element is the quick-connect coupling for hydraulic and pneumatic systems. These couplings allow for rapid disconnection and reconnection of molds, significantly speeding up the changeover time. Additionally, standardized mold base designs promote greater compatibility across different machines, ensuring that molds can be easily swapped out without extensive modifications. Implementing these components not only enhances operational efficiency but also supports a culture of continuous improvement in manufacturing practices. By focusing on these vital aspects, manufacturers can achieve mastery in quick mold change systems and maintain a competitive edge in the industry.

Step-by-Step Techniques for Implementing Quick Mold Change Processes

Implementing quick mold change processes is crucial for enhancing productivity and minimizing downtime in manufacturing. By focusing on step-by-step techniques, manufacturers can streamline operations and improve efficiency. The first step involves thorough planning, where teams assess the current mold change processes and identify bottlenecks. Analyzing the time taken for each step will highlight areas for improvement, which is essential for developing an effective change strategy.

Next, investing in appropriate tools and technologies can significantly expedite mold changes. For instance, utilizing automated systems can reduce manual handling and allow for swift adjustments. Training personnel in these new systems is equally important, ensuring that all team members are adept at using the tools and protocols set out during the planning phase. As companies integrate these step-by-step techniques, they not only enhance operational efficiency but also position themselves to respond quickly to market demands, ultimately leading to sustainability in competitive manufacturing landscapes.

Mastering Quick Mold Change Systems with Practical Step by Step Techniques

| Step | Description | Tools Needed | Estimated Time |

|---|---|---|---|

| 1 | Evaluate current mold change process | Process flowchart | 2 hours |

| 2 | Identify bottlenecks | Data analysis tools | 1 hour |

| 3 | Redesign mold change procedures | CAD software | 3 hours |

| 4 | Train staff on new processes | Training materials | 4 hours |

| 5 | Implement and monitor changes | Monitoring tools | Ongoing |

Best Practices for Training Staff on Quick Mold Change Operations

Implementing effective training for staff on quick mold change operations is crucial for maximizing efficiency and productivity in manufacturing environments. It is essential to create a structured training program that encompasses both theoretical knowledge and practical skills. Begin by providing comprehensive resources outlining the fundamentals of quick mold change systems, ensuring that all employees understand the principles behind these operations.

Tip: Conduct hands-on workshops where employees can practice the quick mold change process under supervision. This not only enhances their understanding but also allows them to familiarize themselves with the equipment. Pair newer employees with experienced mentors to foster a collaborative learning environment.

Moreover, regular assessments and feedback sessions can help identify areas where staff may need additional support. Utilize visual aids and checklists as part of the training materials to reinforce best practices. By encouraging an open dialogue about challenges encountered during the learning process, you empower employees to seek solutions and share insights.

Tip: Implement a reward system that recognizes staff who demonstrate proficiency in quick mold change operations. This encourages a culture of excellence and motivates everyone to strive for improvement, ultimately leading to seamless operations and reduced downtime.

Case Studies: Successful Applications of Quick Mold Change in Chinese Manufacturing

The implementation of quick mold change (QMC) systems in Chinese manufacturing has seen remarkable success, significantly enhancing production efficiency and reducing downtime. According to a report by the China Plastics Industry Association, manufacturers that have adopted QMC techniques have reported a 30% reduction in mold change time, leading to an overall productivity increase of 15% in injection molding operations. This efficiency gain not only optimizes production schedules but also facilitates better responsiveness to market demands.

One notable case study is a leading automotive parts manufacturer in Guangdong province, which implemented a QMC system across its production lines. By integrating standardized mold setups and automated handling equipment, the company achieved mold change times of under 10 minutes. This transformation allowed the firm to decrease its total cycle time, thus improving throughput by approximately 25%. Additionally, the reduction in mold change intervals contributed to a 20% decrease in labor costs, demonstrating the financial benefits of adopting QMC methodologies in a competitive landscape. These case studies exemplify how QMC systems can drive significant advancements in operational efficiency and cost savings in the Chinese manufacturing sector.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी