In the rapidly evolving landscape of manufacturing, the CNC vertical milling machine stands out as a vital tool for enhancing productivity and precision. John Smith, a renowned expert in CNC machining, emphasizes, "Maximizing efficiency with CNC vertical milling machines isn't just about the technology; it's about understanding the processes that drive productivity." As industries increasingly rely on advanced machining technologies, optimizing the use of CNC vertical milling machines becomes paramount for achieving competitive advantage.

The capabilities of CNC vertical milling machines can be vastly enhanced through strategic adjustments and practices that streamline operations. By prioritizing efficiency, companies can reduce waste, increase output, and deliver superior products consistently. This article presents ten actionable tips that can help operators and manufacturers unlock the full potential of their CNC vertical milling machines, ensuring they remain at the forefront of innovation in manufacturing.

Whether you are a seasoned machinist or new to CNC technology, embracing these strategies will lead to smarter production processes and improved overall efficiency. Join us as we explore the essential techniques that can transform your CNC vertical milling operations, helping you to stay competitive in an ever-demanding market.

CNC vertical milling machines are pivotal tools in modern manufacturing, allowing for precise machining of complex parts and materials. Their primary advantage lies in the ability to produce a variety of components with high accuracy and repeatability. Unlike traditional milling machines, CNC vertical mills operate with computer-controlled precision, thereby reducing human error and providing a consistent output quality. This technology is particularly beneficial in industries such as aerospace, automotive, and medical manufacturing, where tolerances and details are of utmost importance.

To maximize efficiency with these machines, it's essential to familiarize yourself with the various settings and capabilities of your CNC vertical milling machine. One key tip is to optimize tool paths by utilizing software that allows for simulation and analysis before actual machining begins. This minimizes wasted time and materials while ensuring that the production process is as streamlined as possible.

Additionally, maintaining your equipment is vital for peak performance. Regular cleaning and calibration help prevent mechanical issues that can lead to unexpected downtimes. Investing in high-quality tools and fixtures further enhances machining efficiency, enabling quicker changeover times and better workpiece holding during operations. By adhering to these practices, manufacturers can fully leverage the advantages of CNC vertical milling machines, driving productivity and profitability in their operations.

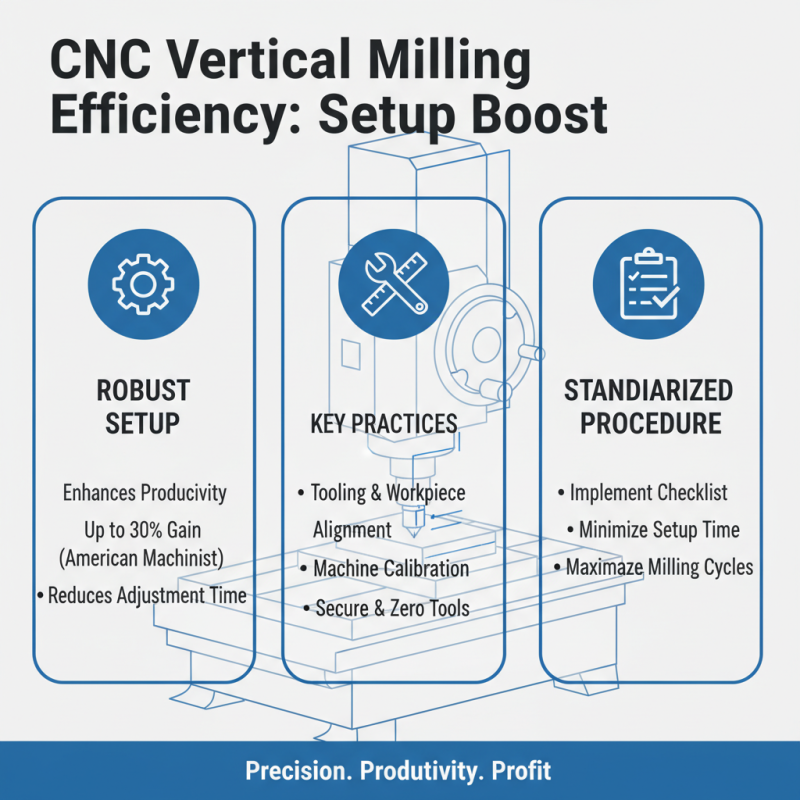

To maximize efficiency with CNC vertical milling machines, establishing a robust setup procedure is paramount. According to a report by the American Machinist, proper setup can enhance productivity by up to 30%. This efficiency boost stems from meticulously aligning tooling and workpieces, which reduces the time spent on adjustments during production runs. Key setup practices include ensuring that the machine is calibrated and that tools are correctly secured and zeroed. Implementing a standardized checklist for setup procedures can help operators minimize setup times and maximize the productivity of each milling cycle.

Additionally, optimizing workholding methods significantly contributes to overall milling efficiency. A study published in the Journal of Manufacturing Processes highlighted that improved workholding techniques can decrease cycle times by as much as 25%. By utilizing fixtures that provide better rigidity and accessibility, operators can enhance chip removal rates and maintain consistent tolerances throughout machining operations. Investing in the right workholding solutions not only streamlines the milling process but also minimizes the risk of operator errors, ultimately leading to higher-quality output.

When selecting the right tools and materials for CNC vertical milling, it is essential to consider the specific requirements of your project.

The choice of cutting tools, such as end mills or face mills, should be based on factors like the material being machined, the desired surface finish, and the complexity of the part design.

Carbide tools, for instance, are favored for their durability and ability to maintain sharp edges, making them suitable for high-precision applications.

Additionally, the geometry of the tool can greatly influence efficiency; choosing the right flute design can enhance chip removal and increase the overall machining speed.

Moreover, the selection of materials is equally crucial. Understanding the properties of the materials you plan to mill—such as hardness, toughness, and machinability—can impact the success of the process.

Metals like aluminum are easier to machine but may require different tooling and speeds compared to harder alloys or exotic materials.

Employing proper tool coatings can also enhance performance, extending tool life and improving resistance to wear.

By carefully assessing both tool selection and material properties, you can optimize your machining process for better efficiency and productivity, ensuring high-quality outcomes.

Regular maintenance is essential for enhancing the performance and longevity of CNC vertical milling machines. The first step in effective maintenance is to establish a routine inspection schedule. During these inspections, operators should check for wear and tear on components such as spindles, bearings, and tool holders. Keeping the machine clean is equally important; dust and debris can accumulate and affect precision. A simple cleaning regime that includes blowing out the coolant passage and wiping down surfaces can prevent minor issues from escalating into significant problems.

Another critical aspect of maintenance is lubrication. Proper lubrication reduces friction between moving parts, which not only extends the life of those components but also ensures smoother operation. It’s vital to follow the manufacturer’s guidelines for lubrication intervals and types of lubricants. Additionally, monitoring coolant levels and quality plays a crucial role in maintaining effective thermal regulation during operation. Regularly changing the coolant not only prevents deterioration but also enhances cutting performance, thus positively impacting machine efficiency. By prioritizing these maintenance practices, operators can significantly improve the reliability and productivity of their CNC vertical milling machines.

Effective workflow and time management are crucial for optimizing CNC vertical milling operations. One of the primary strategies to enhance efficiency is to adopt a well-structured preparation phase. According to a recent industry report by the Association for Manufacturing Technology, 35% of time in machining operations is often lost due to ineffective preparation and tool changes. Streamlining the process by organizing tools, maintaining a dedicated setup area, and ensuring compatibility of materials can significantly reduce downtime. Utilizing digital twins and simulations for setup verification can also minimize errors and expedite the onboarding of new jobs.

Another key aspect is implementing Lean manufacturing principles to maximize productivity and minimize waste. A study published in the Journal of Manufacturing Processes reported that companies adopting Lean approaches in their CNC operations witnessed up to a 25% increase in overall equipment effectiveness (OEE). Techniques such as continuous flow fabrication and 5S methodology for workplace organization can create a more efficient machining environment. Additionally, employing real-time monitoring systems allows operators to track equipment status, identify bottlenecks, and make informed decisions quickly, leading to enhanced operational performance. By focusing on these strategies, businesses can achieve a sustained competitive edge in their milling operations.

© Copyrights Levil Technology Corp 2022