In the rapidly evolving landscape of manufacturing, CNC manufacturing has emerged as a cornerstone for businesses seeking to enhance production efficiency and profitability. As companies face increasing pressure to deliver high-quality products at competitive prices, optimizing CNC manufacturing processes becomes crucial. This approach not only minimizes operational costs but also enhances product quality and customer satisfaction.

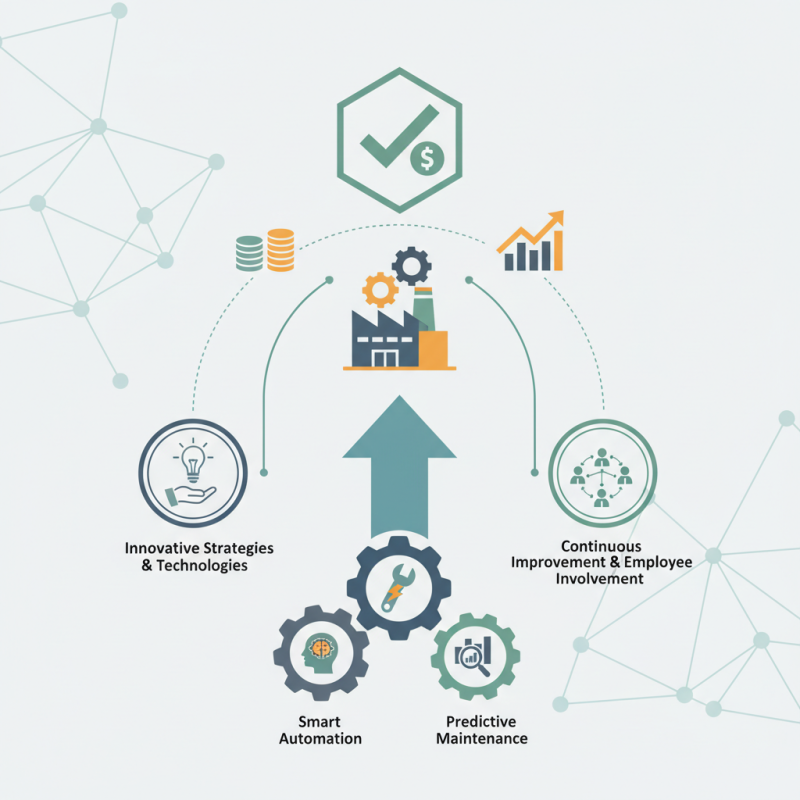

To achieve these goals, manufacturers need to adopt innovative strategies and technologies that streamline workflows, reduce waste, and improve machine utilization. By leveraging advancements such as smart automation, predictive maintenance, and data analytics, businesses can unlock new levels of efficiency and drive profitability. Moreover, fostering a culture of continuous improvement and employee involvement can lead to significant enhancements in CNC manufacturing practices.

In this exploration of optimizing CNC manufacturing, we will delve into key strategies and tools that can transform the production landscape, helping companies not only meet but exceed their performance benchmarks. The focus will be on actionable insights and best practices that can be implemented to create a more efficient and profitable manufacturing environment.

CNC (Computer Numerical Control) manufacturing is a pivotal process in modern production, enabling high precision and efficiency. Understanding its basic components is essential for maximizing productivity. At the core of CNC manufacturing are three key components: the CNC machine itself, the software that drives it, and the tools used for cutting and shaping materials. According to a report by Technavio, the CNC machine tool market is projected to grow by USD 7.72 billion from 2020 to 2024, highlighting the increasing reliance on this technology in various industries.

The software utilized in CNC manufacturing, such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing), plays a crucial role in programming the machines for complex tasks. A recent study by SME (Society of Manufacturing Engineers) indicated that companies employing advanced CNC software witnessed a 25% increase in overall productivity. This emphasizes the importance of investing in top-quality software solutions that optimize the design and manufacturing workflow, allowing for greater efficiency and reduced error rates.

Additionally, the tooling used in CNC manufacturing significantly affects the output quality and operational efficiency. Optimal tool selection and maintenance can reduce cycle times and increase tool life, leading to significant cost savings. According to the American Society of Mechanical Engineers (ASME), companies that focus on effective tool management can realize up to a 15% improvement in production efficiency. By understanding and optimizing these key components, manufacturers can enhance their CNC operations, leading to increased profitability and competitive advantage in the marketplace.

In the ever-evolving landscape of CNC manufacturing, it is vital to analyze current efficiency levels to maximize productivity and profitability. Recent industry reports indicate that, on average, CNC machines operate at only 60-70% of their maximum potential due to factors such as unoptimized workflows, machine downtime, and inefficient tool management. For instance, a survey by a leading manufacturing analytics firm revealed that companies could improve their overall equipment effectiveness (OEE) by up to 30% through targeted optimization strategies.

One critical area to focus on is the optimization of CNC process parameters and setup times. Data shows that reducing setup times can lead to a reduction in lead times by up to 50%, allowing for quicker turnarounds on production orders. Additionally, implementing predictive maintenance based on machine usage patterns can decrease unplanned downtime by 25-40%. By consistently monitoring and analyzing performance metrics, manufacturers can identify bottlenecks and adapt their strategies, leading to significant improvements in both efficiency and profitability. The optimization of CNC processes is not merely an operational adjustment; it represents a strategic imperative for manufacturers aiming to thrive in a competitive marketplace.

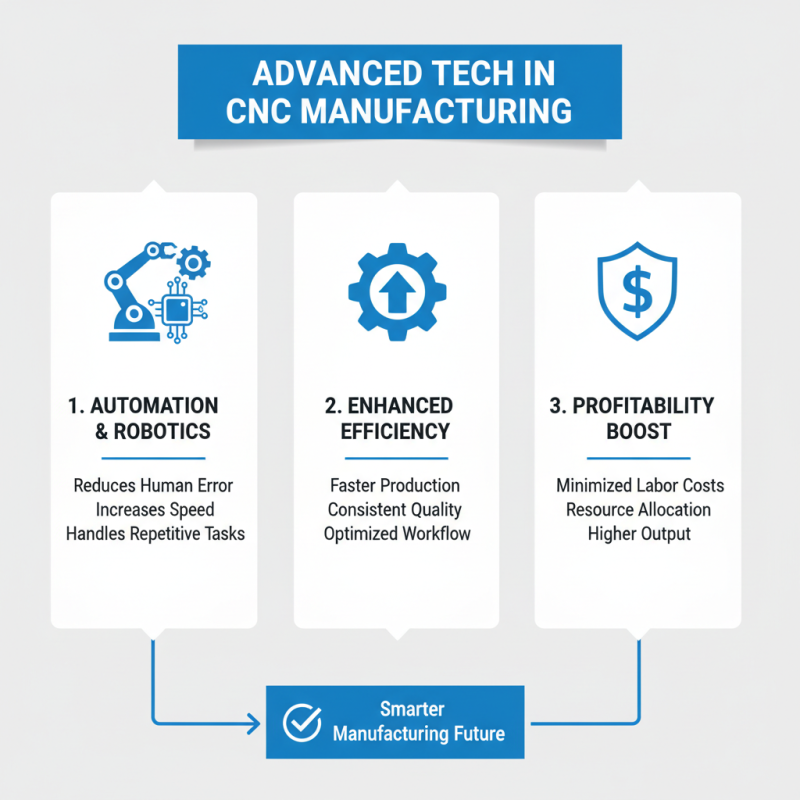

In recent years, the integration of advanced technologies has transformed CNC manufacturing, significantly enhancing efficiency and profitability. One of the pivotal innovations is the implementation of automation and robotics, which reduces human error and increases speed in production processes. By allowing machines to handle repetitive tasks, manufacturers can focus on more complex operations that require human oversight. This shift not only speeds up production but also minimizes labor costs, enabling businesses to allocate resources more effectively.

Another critical advancement is the adoption of data analytics and IoT in CNC systems. By utilizing real-time data collection, manufacturers can monitor machine performance and anticipate maintenance needs, reducing downtime. Predictive analytics empowers companies to optimize their machining processes and improve product quality by identifying inefficiencies early. Additionally, incorporating AI-driven algorithms allows for smarter scheduling and resource allocation, further enhancing operational efficiency. Embracing these technological advancements is essential for CNC manufacturers aiming to stay competitive in an ever-evolving marketplace.

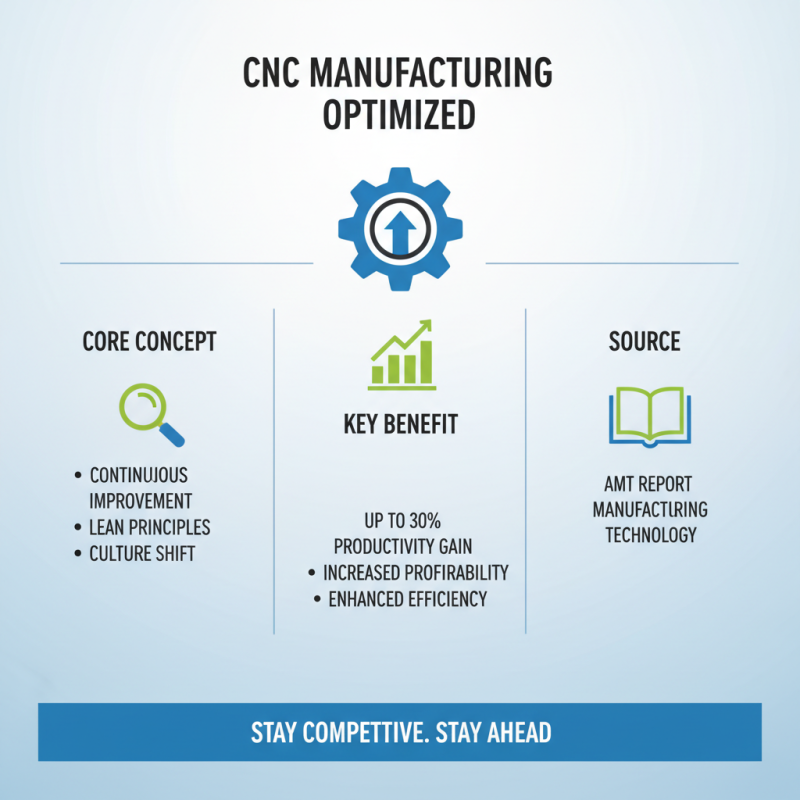

In the pursuit of enhancing efficiency and profitability within CNC manufacturing, continuous improvement strategies play a pivotal role. A recent report by the Association for Manufacturing Technology highlights that manufacturers implementing lean principles can see productivity increases of up to 30%. This underscores that adopting a culture of continuous improvement is not just beneficial but essential for staying competitive.

To successfully optimize CNC operations, manufacturers should focus on process standardization and employee training. Implementing standardized work procedures reduces variability and ensures that all operators can perform tasks consistently. Additionally, investing in employee training programs fosters a skilled workforce, capable of identifying inefficiencies and contributing innovative solutions. Tips for enhancing this aspect include conducting regular training sessions and creating a feedback loop where employees can share ideas on process enhancements.

Moreover, leveraging data analytics can significantly augment decision-making processes. An analysis by the Aberdeen Group indicates that companies utilizing data-driven strategies achieve 20% higher operational efficiency. By tracking machine performance and production metrics, manufacturers can identify bottlenecks and areas needing improvement swiftly. Tips to maximize data usage involve setting clear KPIs and using software systems for real-time monitoring, ensuring that any deviations from the norm are addressed promptly.

Measuring profitability in CNC operations is crucial for optimizing manufacturing processes and ensuring sustainable growth. Key metrics provide valuable insights into operational efficiency and financial performance. One essential metric is the Overall Equipment Effectiveness (OEE), which combines availability, performance, and quality rates to give a holistic view of machine productivity. By regularly assessing OEE, manufacturers can identify bottlenecks, streamline workflows, and reduce downtime, ultimately enhancing their profitability.

Another important metric is the cost-per-part (CPP), which evaluates the total expenses associated with producing each part, including material, labor, and overhead costs. Understanding CPP allows CNC operators to pinpoint areas for cost reduction and invest in more efficient machining methods or technologies. Additionally, tracking utilization rates helps companies measure how effectively they are using their machinery and resources. By focusing on these key metrics, CNC manufacturers can make informed decisions that drive efficiency and increase profitability in their operations.

© Copyrights Levil Technology Corp 2022