Revolutionizing Manufacturing Efficiency: What is the Best Mold Cart System and Its Industry Applications?

In the rapidly evolving landscape of global manufacturing, efficiency and precision are paramount, particularly in China, where the push for quality upgrades is transforming the industry. A pivotal innovation in this realm is the Mold Cart System, designed to streamline the transportation and management of molds within manufacturing plants. According to a report from the National Association of Manufacturers, optimizing production processes can lead to cost reductions of up to 25% and productivity improvements of over 20%. The implementation of advanced Mold Cart Systems not only contributes to these efficiencies but also enhances safety and reduces downtime, addressing the growing need for better resource management in factories.

This blog will explore the best Mold Cart Systems currently available and their diverse applications across the industry, demonstrating how they play a crucial role in maintaining China's competitive edge in global manufacturing.

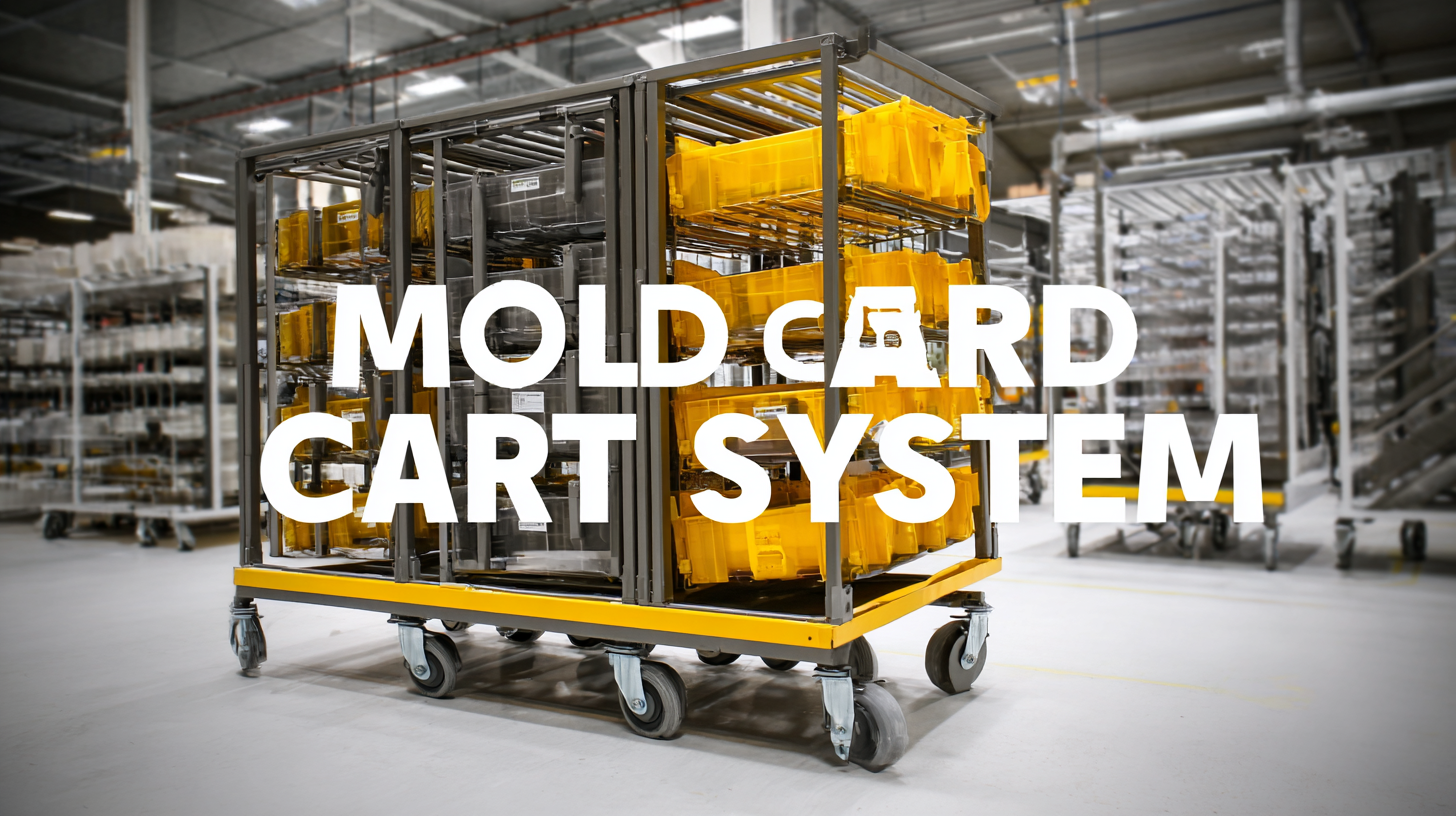

Key Features of Mold Cart Systems for Streamlining Manufacturing Processes

Mold cart systems play a crucial role in revolutionizing manufacturing efficiency, particularly in industries like automotive, aerospace, and consumer goods. According to a recent market report by Research and Markets, the global mold cart systems market is expected to grow significantly, driven by an increasing demand for lean manufacturing practices. The key feature of these systems is their ability to streamline workflow by minimizing the time spent on transporting molds between various stations. Enhanced mobility, ergonomic designs, and customizable configurations help in reducing setup times by over 30%, which is vital in high-paced manufacturing environments.

Moreover, modern mold cart systems incorporate advanced technologies such as RFID tracking and IoT connectivity. These features enable real-time monitoring of mold locations, improving inventory management efficiency by as much as 25%. A study by the International Journal of Production Research highlights that implementing automated mold cart systems not only reduces labor costs but also elevates overall production quality. With businesses increasingly focusing on automation and efficiency, investing in a robust mold cart system can lay the groundwork for significant productivity gains and long-term competitiveness in manufacturing.

Revolutionizing Manufacturing Efficiency: Best Mold Cart System and Its Industry Applications

| Feature | Description | Industry Application |

|---|---|---|

| Weight Capacity | Supports up to 2000 lbs of molds and tooling. | Injection Molding |

| Mobility | Equipped with heavy-duty wheels for easy transportation. | Automotive Manufacturing |

| Customization | Available in various sizes and configurations to fit specific mold types. | Electronics Manufacturing |

| Safety Features | Includes safety locks and secure mold holding mechanisms. | Aerospace Industry |

| Ergonomic Design | Designed to reduce strain on workers during mold handling. | Consumer Products |

| Storage Solutions | Integrated shelving for organizing tools and components. | Medical Device Manufacturing |

| Durability | Constructed from high-strength materials for long service life. | Food Processing |

Comparative Analysis of Different Mold Cart Systems and Their Performance Metrics

In the landscape of modern manufacturing, the efficiency of mold handling plays a crucial role in operational effectiveness. A comparative analysis of different mold cart systems unveils significant variations in performance metrics, such as load capacity, maneuverability, and stability. For instance, traditional mold carts typically offer basic functionality with limited weight support, which can hinder productivity in large-scale operations. In contrast, newer systems equipped with advanced materials and ergonomic designs significantly enhance user experience by reducing labor strain and increasing transport speeds.

Another essential aspect to consider is the integration of technology in mold cart systems. Many contemporary models include features such as GPS tracking, real-time data analytics, and automated lifting mechanisms, which contribute to higher productivity rates and better inventory management. The ability to monitor mold carts remotely provides manufacturers with valuable insights into operational efficiency, allowing them to make data-driven decisions. By assessing these performance metrics, businesses can choose the most suitable mold cart system tailored to their specific manufacturing needs, ensuring they remain competitive in a rapidly evolving industry.

Industry-Specific Applications of Mold Carts in Automotive Manufacturing

In the automotive manufacturing sector, efficiency is paramount, and the use of advanced mold cart systems has transformed production processes. A recent report by the International Journal of Advanced Manufacturing Technology indicates that companies utilizing specialized mold cart systems can reduce cycle times by up to 30%, thereby increasing throughput significantly. This is particularly crucial in the automotive industry, where the demand for precision and rapid delivery is ever-increasing.

Mold carts facilitate streamlined workflows by enabling easy transport of molds between different stages of manufacturing. For instance, a survey conducted by the American Mold Builders Association found that 75% of automotive manufacturers have adopted mold cart systems, reporting not only enhanced mobility but also improved safety and ergonomics on the shop floor. In addition, the integration of RFID technology into these systems has allowed for better tracking and inventory management, further advancing operational efficiency. As automotive production becomes more complex, the role of mold carts will undoubtedly evolve, underscoring their significance in optimizing manufacturing efficiency.

Impact of Mold Cart Technology on Production Efficiency and Cost Reduction

The integration of advanced mold cart systems significantly enhances production efficiency and cost-effectiveness in manufacturing. By streamlining the handling and organization of molds, companies can reduce lead times and minimize downtime between production cycles. This newfound efficiency is especially pertinent in industries such as automotive manufacturing, where lightweight materials are becoming increasingly critical. The transition to lightweight materials not only improves fuel efficiency but also necessitates precise and quick mold operations to keep up with the fast-paced production demands.

The integration of advanced mold cart systems significantly enhances production efficiency and cost-effectiveness in manufacturing. By streamlining the handling and organization of molds, companies can reduce lead times and minimize downtime between production cycles. This newfound efficiency is especially pertinent in industries such as automotive manufacturing, where lightweight materials are becoming increasingly critical. The transition to lightweight materials not only improves fuel efficiency but also necessitates precise and quick mold operations to keep up with the fast-paced production demands.

Tips: Consider implementing a digital twin technology in conjunction with your mold cart system. This will allow for real-time monitoring and adjustments, ultimately leading to better decision-making and resource allocation. Additionally, investing in innovative systems that reduce tooling lead times can provide a competitive edge, enabling manufacturers to respond more rapidly to market changes.

The utilization of advanced materials and molding technologies can also influence production costs. With methods like co-molding composite materials, manufacturers can achieve higher strength and durability at reduced weights, potentially decreasing material expenses. Adopting these technologies not only streamlines processes but also aligns with sustainability goals, further reinforcing the overall efficiency of production systems.

Future Trends in Mold Cart Design and Innovation for Enhanced Manufacturing Productivity

The landscape of manufacturing is rapidly evolving, driven by the need for increased productivity and efficiency. One of the most significant trends in mold cart design is the integration of smart technologies. Advanced sensors and IoT devices are being incorporated into mold carts to monitor load capacities, track usage, and identify maintenance needs in real-time. This not only enhances operational efficiency but also reduces downtime by allowing for predictive maintenance, ensuring that manufacturers can maximize their output without interruptions.

Another emerging trend is the modularity and customization of mold cart systems. As manufacturing processes become more specialized, the demand for adaptable equipment grows. Manufacturers can now customize mold carts to suit specific workflows, incorporating expandable features that allow for swift adjustments in configuration. This flexibility leads to a more streamlined operation, enabling teams to respond quickly to changing production needs while maintaining high levels of productivity. In an industry where agility can determine success, embracing these innovative mold cart designs is a strategic move for forward-thinking manufacturers.

Revolutionizing Manufacturing Efficiency: Mold Cart System Impact

This bar chart illustrates the impact of mold cart systems on various aspects of manufacturing efficiency, showcasing the percentage of improvements in operational efficiency, cost reduction, time savings, flexibility, and quality enhancement.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी