In the rapidly evolving landscape of manufacturing, CNC machining technology stands at the forefront of innovation, dramatically reshaping production processes and capabilities. As industries strive for precision, efficiency, and scalability, this advanced technology is not merely an improvement over traditional methods but a game changer that is redefining the future. According to Dr. Emily Roberts, a renowned expert in the field of manufacturing technology, "CNC machining technology is transforming the way we think about production; it enables unprecedented accuracy and flexibility in design implementation."

In the rapidly evolving landscape of manufacturing, CNC machining technology stands at the forefront of innovation, dramatically reshaping production processes and capabilities. As industries strive for precision, efficiency, and scalability, this advanced technology is not merely an improvement over traditional methods but a game changer that is redefining the future. According to Dr. Emily Roberts, a renowned expert in the field of manufacturing technology, "CNC machining technology is transforming the way we think about production; it enables unprecedented accuracy and flexibility in design implementation."

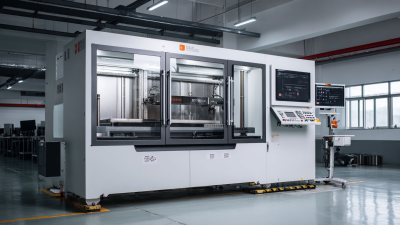

As organizations invest in CNC machining technology, they are reaping the benefits of streamlined operations and enhanced product quality. This technology allows for intricate designs to be produced with remarkable consistency, reducing waste and lead times while bolstering overall productivity. The integration of CNC machines into manufacturing environments empowers engineers and designers to push the boundaries of creativity, offering the potential for bespoke solutions that cater to diverse market demands.

In conclusion, CNC machining technology is not only a pivotal element of modern manufacturing; it is a catalyst for change that will influence how products are conceived, created, and delivered in the future. As the industry continues to embrace these advancements, the implications for competitiveness, innovation, and sustainability are profound, paving the way for a new era in manufacturing excellence.

The evolution of CNC machining technology has marked a significant transformation in the manufacturing landscape. Starting from its inception, CNC machining has undergone numerous milestones, beginning with the advent of numerical control systems in the 1940s. These early systems paved the way for the integration of computers into manufacturing processes, enhancing precision and efficiency. Over the decades, advancements such as 3D modeling software, real-time monitoring, and automation have pushed boundaries, enabling manufacturers to create complex parts with remarkable accuracy.

Innovation has continued to shape CNC machining, particularly with the rise of digital technologies. Modern CNC machines are now equipped with features like adaptive learning algorithms, which facilitate self-optimization during machining operations. Furthermore, the integration of IoT and artificial intelligence allows for predictive maintenance and smart manufacturing solutions, reducing downtime and enhancing productivity. This continual evolution underscores the importance of CNC technology in the circular economy, paving the way for sustainable and efficient manufacturing practices that will define the future of the industry.

CNC machining technology is transforming modern manufacturing by offering precision and efficiency that traditional methods struggle to match. One of the primary benefits of CNC (Computer Numerical Control) machining is its ability to produce complex geometries with remarkable accuracy. This level of precision not only reduces waste but also enhances product quality, enabling manufacturers to meet the more stringent demands of today's market. Moreover, CNC machines can operate continuously, which significantly decreases production time and increases output.

Another key advantage of CNC machining lies in its versatility. Manufacturers can quickly switch from one project to another with minimal downtime by simply reprogramming the machines. This flexibility allows businesses to adapt to shifting market needs and custom orders without requiring extensive retooling or setup. Furthermore, the integration of CNC technology also minimizes human error, resulting in a more reliable production process. Overall, the adoption of CNC machining technology is driving innovation and competitiveness in the manufacturing sector, making it an essential component of future-ready operations.

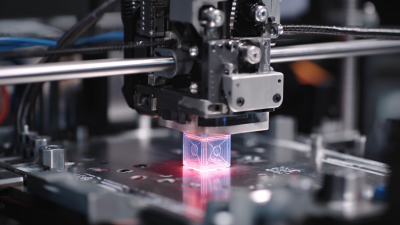

Cutting-edge technologies are redefining CNC machining efficiency, presenting unparalleled opportunities for manufacturers. Innovations such as AI-powered CNC routers and advanced waterjet cutting systems not only enhance precision but also streamline production processes. For instance, the latest 5-axis CNC machines can execute complex geometries with remarkable accuracy, resulting in significant time and cost savings.

**Tips:** When considering technology adoption, prioritize solutions that offer a combination of efficiency and sustainability features. Additionally, invest in workforce upskilling to ensure that your team is equipped to handle new tools and methodologies. This investment in both technology and people can lead to transformative changes on the shop floor.

The impact of digitalization, AI, and IoT on manufacturing continues to intensify, facilitating better integration between machines and processes. Manufacturers are urged to stay ahead by embracing these innovations; those who do can gain a significant competitive advantage. Tailoring CNC solutions to specific operational needs will enable companies to optimize their production capabilities and achieve higher quality outputs.

**Tips:** Embrace continuous learning and adaptation within your organization to fully leverage new technologies. Implement pilot projects to test the effectiveness of new approaches before broader application, ensuring a smoother transition and better results.

CNC machining technology is at the forefront of enhancing manufacturing efficiency, with sustainability emerging as a critical focus. This advanced technique minimizes waste through precision engineering, allowing manufacturers to achieve high-quality outputs with minimal material expenditure. Traditional manufacturing often leads to significant scrap and excess, but CNC machining precisely cuts materials according to exact specifications, significantly reducing the leftover material. This reduction not only decreases the overall cost of production but also promotes responsible sourcing and utilization of resources.

Moreover, the energy consumption associated with CNC machining is being optimized through innovative technologies such as energy-efficient motors and advanced cooling systems. By integrating software that provides real-time monitoring and analysis of operational processes, manufacturers can identify and rectify inefficiencies, thereby lowering their carbon footprint. As industries increasingly prioritize sustainability, CNC machining stands out as a vital contributor to greener practices in manufacturing, paving the way for a more environmentally conscious future.

As we look ahead to the next decade, CNC machining technology is expected to play a pivotal role in the evolution of manufacturing processes. By 2030, the integration of Industry 4.0 principles—such as automation, data exchange, and advanced analytics—will transform traditional machining methods into smart manufacturing solutions. This transition will facilitate unprecedented levels of precision, efficiency, and adaptability, enabling manufacturers to respond more swiftly to changing market demands.

Additionally, trends such as the rise of additive manufacturing, particularly 3D printing, will significantly influence CNC machining practices. The synergy between these technologies will allow for more complex designs and faster production times, pushing the boundaries of what is possible in manufacturing. Experts predict that advancements in materials, machine capabilities, and software technologies will provide manufacturers with the tools needed to innovate and thrive in an increasingly competitive landscape. As these trends unfold, stakeholders must remain agile and forward-thinking to harness the full potential of CNC machining in the years to come.

© Copyrights Levil Technology Corp 2022