Choosing the right 4 axis milling machine can be a daunting task, especially with the myriad of options available in the market today. With advancements in technology, the capabilities of milling machines have significantly evolved, making them essential tools for various industries including aerospace, automotive, and manufacturing. A well-chosen 4 axis milling machine can enhance production efficiency, precision, and ultimately, the quality of finished products.

To navigate through the complexities of selecting the perfect machine, it is crucial to understand the key factors that influence its performance and suitability for your specific applications. This guide presents ten essential tips that will aid in making an informed decision, taking into consideration aspects such as machine specifications, intended use, budget constraints, and additional features.

Whether you are a seasoned professional or new to the world of machining, finding the appropriate 4 axis milling machine can lead to significant improvements in your operational capabilities. Let’s delve into these vital considerations that will empower you to choose wisely.

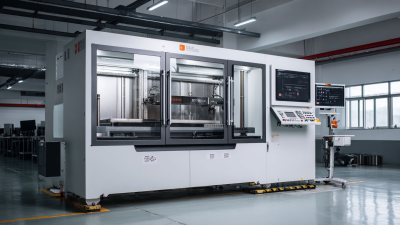

4 axis milling machines are powerful tools that enhance the capabilities of traditional CNC machining by adding a fourth axis. This additional axis allows for complex geometries and intricate designs, making them ideal for industries such as aerospace, automotive, and medical. Understanding how these machines operate is crucial for users looking to optimize their manufacturing processes. The fourth axis typically refers to the rotational movement around the X-axis, enabling the milling of complex shapes that would otherwise require multiple setups.

Choosing the right 4 axis milling machine requires a clear understanding of the machine's specifications and features. Key elements to consider include the machine's build quality, precision, and compatibility with different materials. It's also essential to assess the control systems and software that come with the machine, as they greatly influence usability and the range of operations you can perform. By grasping these basics, users can make informed decisions that meet their operational needs and improve overall productivity.

When selecting a 4 axis milling machine, understanding the key features is crucial for making an informed decision. One primary consideration is the machine's precision. Look for models that offer high-speed spindle capabilities and state-of-the-art CNC controls, as these elements will significantly enhance the accuracy of your machining tasks. Additionally, a robust and rigid machine frame is essential to minimize vibrations and maintain stability during cutting operations.

Another important feature to examine is the machine's software compatibility. A 4 axis milling machine equipped with intuitive, user-friendly software can streamline your workflow and reduce operator errors. Furthermore, consider the versatility of the machine. A model that supports various tooling options and can easily adapt to different materials will be a valuable asset to your production line. Lastly, assess the availability of technical support and spare parts, as reliable service can make a significant difference in minimizing downtime and maintaining productivity.

When selecting a 4 Axis Milling Machine, material compatibility is a crucial factor that can significantly influence your decision. Different materials require specific machining properties and considerations. For instance, metals and plastics have varying degrees of machinability, affecting the choice of tools and the machine's design features. Understanding how each material interacts with the capabilities of the milling machine helps ensure optimal performance, longevity, and cost-effectiveness.

Moreover, the advancements in material science, such as developments in 3D printing filaments, highlight the growing diversity in material properties. From standard materials like PLA to high-performance options like PEEK, each type can impact the milling process differently. Additionally, compatibility of materials with sterilization techniques, particularly in medical applications, emphasizes the need for machines that can handle specific material requirements without compromising quality. Thus, evaluating material compatibility is not just about what can be machined, but also about achieving the desired outcomes in various applications.

| Material Type | Machine Compatibility | Comments |

|---|---|---|

| Aluminum | High Compatibility | Ideal for faster machining speeds and lower tool wear. |

| Steel | Moderate Compatibility | Requires more robust machines with higher torque. |

| Titanium | Low Compatibility | High tool wear; specialized machines often needed. |

| Plastic | High Compatibility | Easier to machine, suitable for prototyping. |

| Composite Materials | Variable Compatibility | Depends on fiber and resin type; some machines suitable. |

When considering the purchase of a 4-axis milling machine, understanding the size and space requirements for your shop is crucial. This aspect not only affects the machine's operation but also impacts overall workflow. Research indicates that inadequate space can lead to a 20-25% decrease in productivity due to restricted movement and workflow disruptions. It's essential to measure your available workspace and ensure that your new machine, along with any additional tools or materials, can fit comfortably.

To make informed decisions, keep in mind the following tips: First, assess the dimensions of the 4-axis milling machine, including its operational footprint, clearance needs, and any required connections for power and air supply. Second, consider the layout of your shop to maximize efficiency—arranging tools for easy access can enhance productivity significantly. For example, studies suggest that a well-organized workstation can improve task performance by up to 30%. Finally, ensure that there is enough room for both operators and equipment movement, as a crowded space poses safety risks and can hinder machine performance.

When choosing the right 4 axis milling machine, a crucial consideration is the delicate balance between cost and features, particularly for optimal performance. According to a report by the Association for Manufacturing Technology, investing in advanced features can enhance a machine's capability, potentially increasing productivity by up to 30%. However, this doesn’t always mean opting for the most expensive model; it's essential to evaluate which features genuinely contribute to your specific machining needs.

One tip to consider is assessing the precision of the milling machine, as high-precision machines can reduce waste and increase product quality, ultimately lowering costs in the long run. Another point to evaluate is the machine's versatility, which allows for a wider range of applications, making it a better investment. Additionally, ensure you factor in the ongoing operational costs, such as maintenance and tooling, where machines with higher upfront costs may offer lower overall expenses due to better efficiency and durability over time.

© Copyrights Levil Technology Corp 2022